Problem

As part of their policy of constant improvement and updating, Southern Water had identified that an opportunity existed to improve consistency of performance, energy consumption and maintenance costs at their Testwood Works.

These changes called for the replacement of an existing dynamic flash mixer to ensure improved process performance together with reduced running costs.

Solution

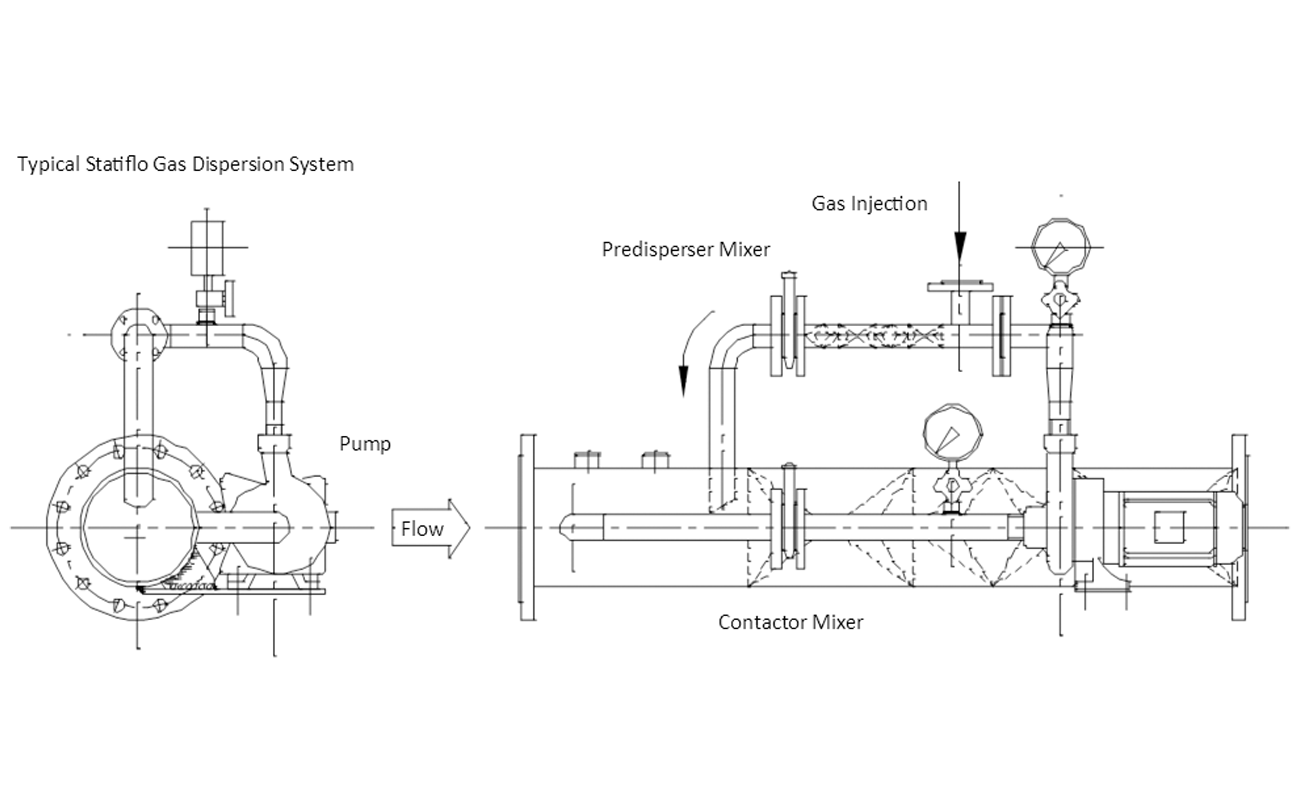

Southern Water’s engineers decided to replace the outdated machinery with state of the art static mixing technology from Statiflo.

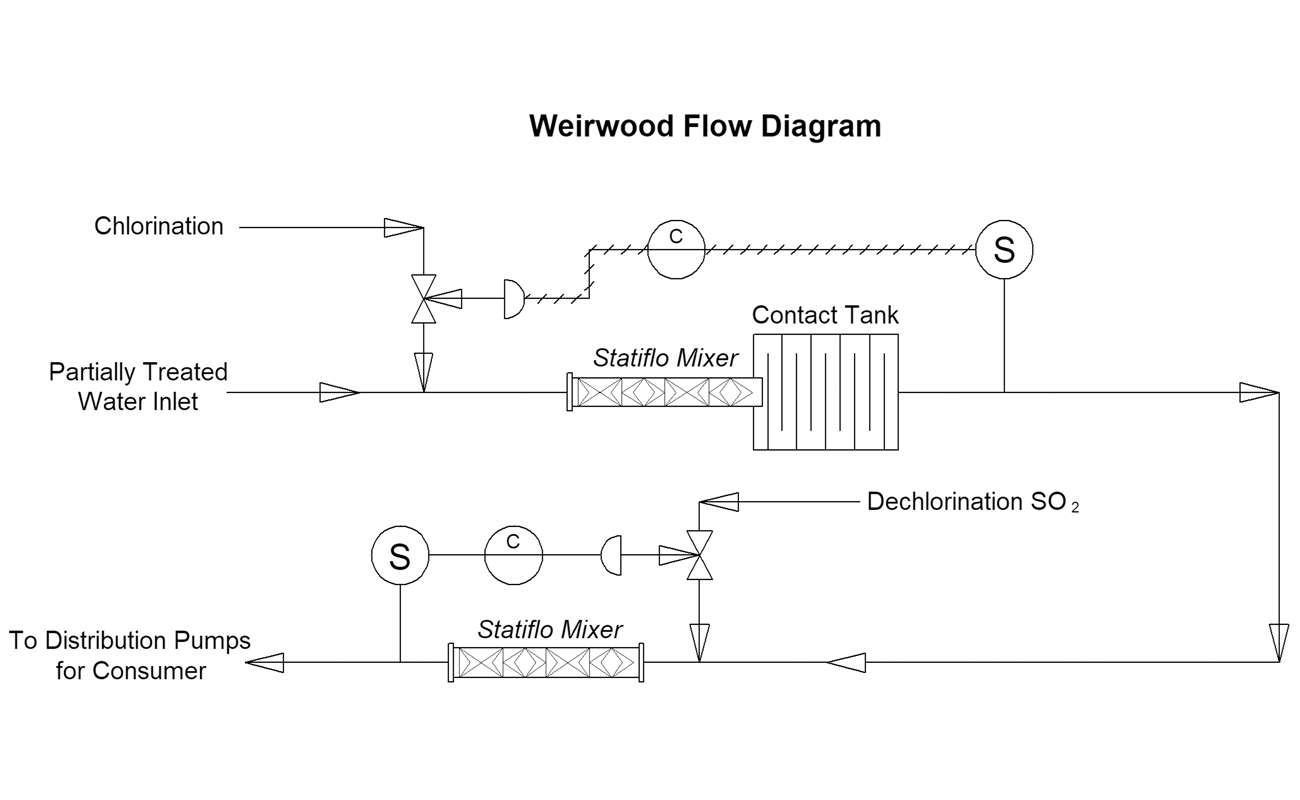

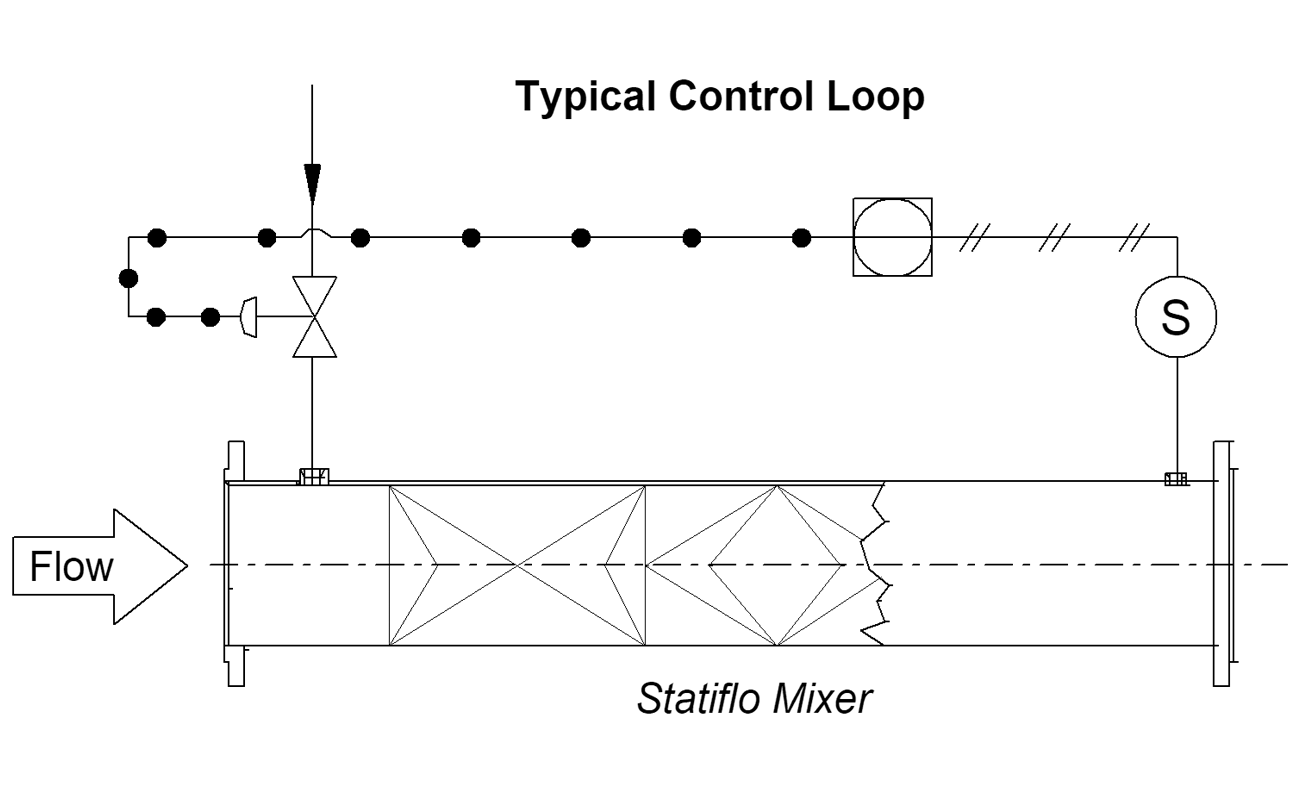

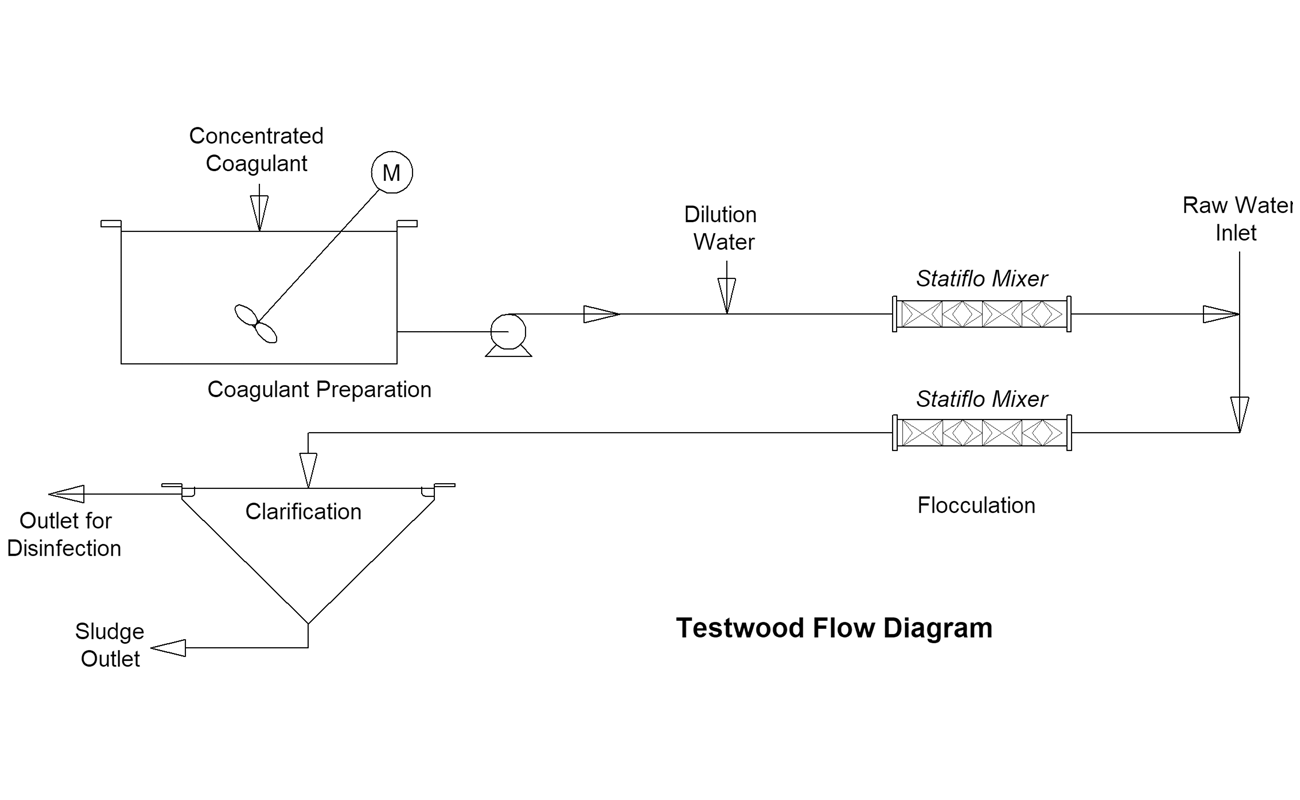

Incorporating a 600mm NB Statiflo Motionless Mixer at the inlet works ensured the total and efficient distribution of dosed coagulant uniformly throughout the treated water. The mixer also substantially enhanced coagulation by applying a regular and controlled shear to the raw water which improved the flocculation process thereafter (Floc Mixer). A streaming current detector was also incorporated to control coagulant dosage.

Result

The installation of the Statiflo Motionless Mixer was a spectacular success. Excessive chemical consumption was vastly reduced, as were the substantial energy and maintenance costs. The Statiflo Mixer operates with no moving parts, no spare parts requirements and no maintenance whatsoever. The small head loss penalty of 130mm WG (at 20 MLD) equated to an actual power consumption of a mere 0.3kw as opposed to the 15kw required by the original dynamic flash mixer.

Substantially improved process performance was also achieved producing water of previously unseen quality. The reduction in chemical consumption alone would have resulted in a payback of the mixer capital cost within one year, but the high level of energy savings recorded meant that payback was in fact achieved in a matter of weeks.

- No moving parts for virtually maintenance-free operation

- Low energy consumption

- Low capital cost

- Eliminates overdosing

- Chemical injection rates reduced to a minimum

- Minimal space requirements

- Completely sealed system

- Predictable blending and dispersion formation

- Eliminates radial gradients

- Approaches deal plug flow

- Self cleaning

- Improved process control & product quality

- Processes all pumpable material in laminar or turbulent flow

- Available in small and large diameters

- Manufactured in all commercially available materials

- Designs available for open channel and rectangular duct systems

- Can be installed in bends to save space

- Custom designs to meet special specifications

- Manufactured to meet all levels of QA/QC

- Low installed weight