Difference Between Mixer Efficiency and Mixture Quality

Unfortunately, these terms are often used interchangeably, especially in process specifications for static mixers. It is important to understand the difference between mixer efficiency and mixture quality in order to correctly specify the performance requirements of a static mixer.

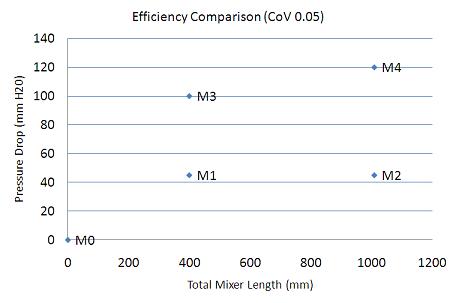

Mixture quality (Coefficient of Variation – CoV) defines the mixing objective and, for most applications, a CoV of 0.05 will ensure complete homogeneity. Mixer efficiency, on the other hand, indicates how the mixing objective is reached and not the objective itself. The same mixture quality can usually be achieved by both inefficient and efficient designs of static mixers:

-

An inefficient mixer design will have a relatively high pressure drop and/or a long mixing length

-

An efficient mixer design will have a relatively low pressure drop and/or a short mixing length

BHR Group Ltd has developed an interesting method of comparing the efficiencies of different designs of static mixers on the basis that a mixer with zero energy consumption (no pressure drop) and with zero length (instantaneous mixing) would have a theoretical 100% mixing efficiency.

In this illustration four different static mixers (M1, M2, M3 & M4) are used on the same mixing system with identical process conditions, to achieve the same mixture quality (CoV). The mixer lengths (mixing times) and pressure drop (energy consumption) are then plotted:-

M0 represents a theoretical mixer with 100% efficiency

M1 is the most efficient mixer

M2 is less efficient in terms of mixing time

M3 is less efficient in terms of pressure drop

M4 is less efficient in terms of both mixing time and pressure drop

The largest savings in additive consumption and energy are only available from the most efficient design.

Detailed comparisons of mixer efficiencies for all the commonly available proprietary mixers, for both pipe and open channel designs, are available to members of BHR’s research consortiums (see research & development).