The Brewing Industry

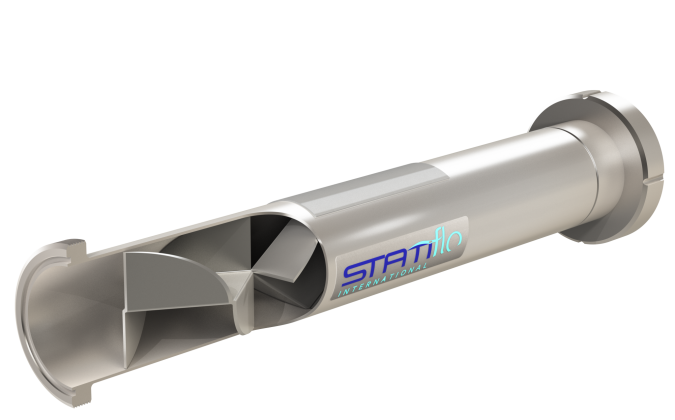

In an increasing cost conscious world, we are all striving to improve our effectiveness. Process equipment which has no moving parts, which is maintenance free, very energy efficient and which can improve plant performance will significantly contribute towards lower operating costs. It is proven that inline static mixing is now playing a significant role in the brewing industry.

Statiflo Motionless Mixers have many applications in all types of breweries and microbreweries, from simple blending operations to complex inline reactors involving heat exchange.

Below you can find some brief details of applications which we have supplied static mixers for but to find out more about how we can help with your specific application, contact us today.

In assessing the benefits of Statiflo Inline Static Mixers it is important to remember:

- Overall length can be varied to suit space limitations.

- Element geometry can be designed for both high and low head loss systems.

- Large diameter – no theoretical upper limits.

- Elements for rectangular or other unusually shaped ducts and open channels

- Special designs for incorporating in bends, offer space saving and minimal disturbance to piping systems.

- Guaranteed highly efficient mixing.

- No moving parts provide a maintenance free operation.

- Reduction in operational energy costs, as no direct power is required.

- Ease of installation.

- Minimal space requirements with no upstream or downstream pipe lengths required. Providing short control process times in applications where quick process response control is critical.

- Short process chemical dosing control loops provide optimum performance in response to rapidly changing process conditions, as well as reducing chemical costs.

- Available in a wide ranges of sizes and material to suit most applications.

- Each unit is custom designed benefiting from Statiflo’s long term experience in designing and manufacturing static mixers to the highest of standards.

- Total support is provided by highly trained engineers situated in Statiflo regional country offices and a world wide representative network.

Application Examples and Case Studies

Brewing Industry

The Statiflo Motionless Mixer is used in all process industries for the mixing of two or more miscible or immiscible liquids.

As a general rule, if the material is pumpable, then it can be mixed – high viscosity is not a problem.

Both laminar flow mixing or high viscosity liquids and turbulent flow mixing of low viscosity liquids enabling predictable homogenisation and concentration distributions, resulting in improved yields and better product properties.

We are not aware of any other device able to achieve a lower energy input per degree of mix.

Brewing Industry

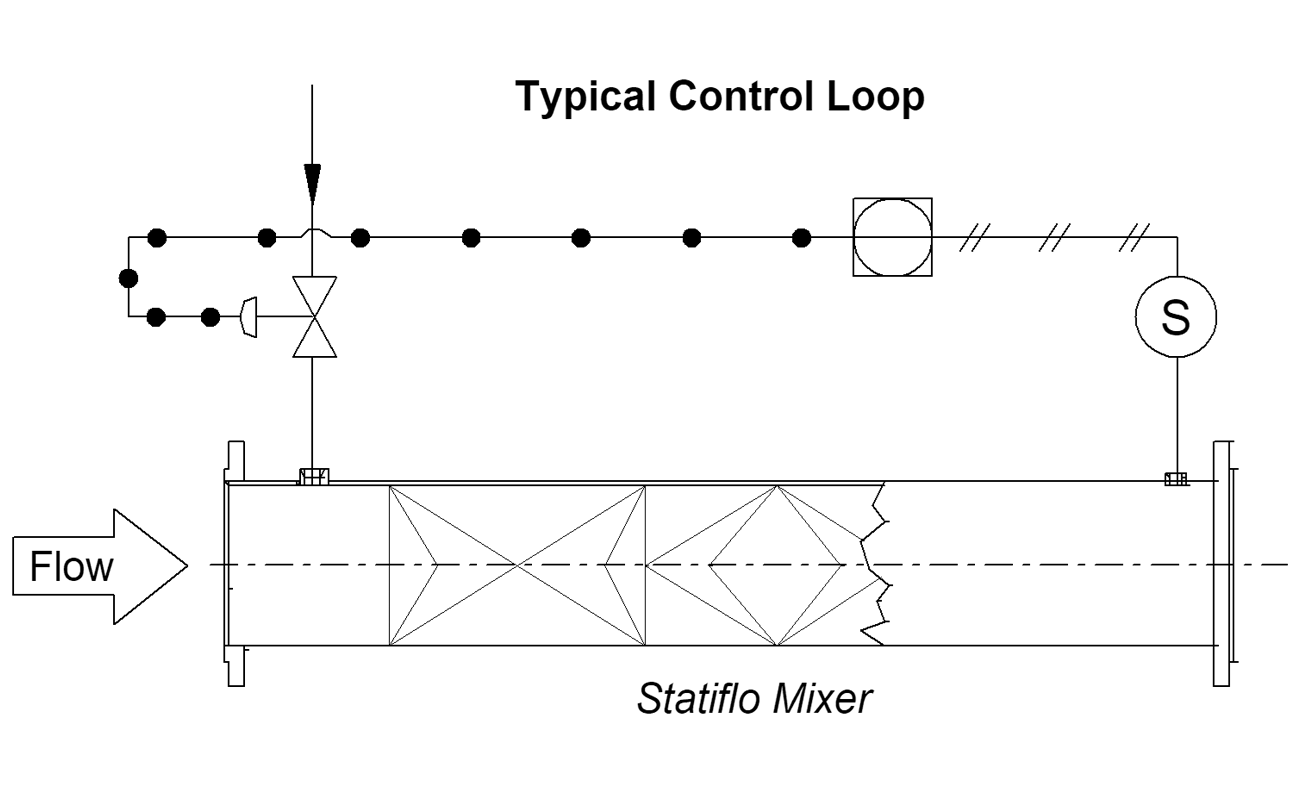

The Statiflo Motionless Mixer is a vital component of any inline mixer/control system. Even the most sophisticated control system will not perform completely effectively if the measuring equipment fails to see a representative sample.

Modern process control systems are usually very expensive and despite the mixer being only a small fraction of the total cost, its role as an essential component, vital to plant performance, it’s often overlooked

Installing a Statiflo Motionless Mixer allows sampling immediately downstream, within very few diameters of the injection point. This permits the system to rapidly adjust to monitored process changes with negligible time lag and minimum use of dosing additives.

The vital role in CIP systems for Statiflo Motionless Mixers is not indicated on the flow sheets. All critical fermentation equipment must be sterilised at regular intervals, with hot caustic or hypochlorite solutions, which are prepared, diluted and heated using Motionless Mixers.

The mixers are installed in a simple, compact process control loop where for example, concentrated caustic or Sodium hypochlorite are continuously diluted inline to ensure correct and accurate concentration of sterilising agent is present in the CIP solution before use.

After chemical preparation, the CIP solution is often heated, by a Statiflo Motionless Mixer either by adding hot water or steam.

Virtually all breweries precondition the water supply in a variety of ways dependent upon feedwater quality.

Statiflo Motionless Mixers are installed for pH control, using either sulphuric acid or sodium hydroxide solution for pH correction.Water hardness is controlled using calcium and phosphate salts.

The mixers are installed to ensure complete mixing and dilution of injected concentrated chemical takes place, enabling representative sampling, for process control purposes, to occur immediately downstream. This results is minimum system response and ‘on spec’ product.

This stage involves dissolving the maximum available soluble fermentation sugars from the malted barley in warm water. It is carried out in most breweries by firstly mashing, followed by sparging.

The dissolving of fermentation sugars is a temperature critical process often carried out at different mashing and sparging water temperatures. Cold water and steam are normally readily available, however, the provision of warm water at the differing temperatures required for the processes below is not so simple.

Bulk preparation and storage of warm water at three or four different temperatures is often costly, cumbersome and occasionally almost impossible.

- Mashing: malted barley is conveyed into the mash tun where it is infused with warm water, prepared with Statiflo Motionless Mixers and gently agitated. This allows the soluble sugars (maltose,etc) to dissolve. The resultant concentrated ‘mash liquor’ is then pumped from the mash tun to a holding vessel for combination with sparged liquor.

- Sparging: spent grains from mashing are transferred to the Lautertun where further warm water, again prepared with Statiflo Motionless Mixers, is sparged over the grains to wash and rinse the maximum amount of residual fermentation sugars from the grain. The resultant dilute solution of malt sugars, the ‘sparge liquor’, is transferred to a holding vessel via a further Statiflo Motionless Mixer for wort density control.

Brewing Industry

For optimum fermentation, the wort density must be carefully controlled to ensure the ideal concentration of sugars is present for rapid yeast growth and subsequent anaerobic fermentation.

A Statiflo Motionless Mixer blends mashing malt liquor, sparge liquor and warm water to give wort with correct gravity for fermentation.

The Statiflo Motionless Mixer uniformly blends all three components to provide accurate density control at the mixer outlet. Process control can then be applied to any of the three components feed lines, using proportional control to maintain consistent wort density.

Brewing Industry

As brewery capacity has increased over the years, the time taken for the yeast population to grow aerobically to an acceptable level prior to anaerobic fermentation has become prohibitive. To reduce this lost fermentation time, accelerated aerobic yeast growth can be achieved by increasing the oxygen content of the wort prior to yeast inoculation. This ensures that the rapid cell growth occurs in an oxygen rich wort, such that very high yeast populations are quickly reached, reducing delays in starting anaerobic fermentation.

If gas injection takes place in an empty pipe, the oxygen bubbles quite rapidly recoalesce and a two phase system quickly develops with the wort in the lower half of the pipe and the gas in the upper half. Efficient mass transfer is impossible under these conditions.

Statiflo Motionless Mixers solve this problem and increase mass transfer rates. Oxygen is introduced at the Mixer inlet, sometimes through a sintered diffuser, to ensure that the gas is rapidly dispersed uniformly throughout the wort in the form of very fine bubbles. The even shear characteristics of the Mixer results in a narrow bubble size distribution curve .

Maintaining the fine gas bubbles in suspension for a given time interval promotes high mass transfer rates, resulting in high oxygen content in the wort. The oxygen rich environment is ideal for rapid aerobic yeast growth and subsequent anaerobic fermentation.

The finely suspended solids in the cloudy beer are removed by injection of finings, using a Statiflo Motionless Mixer for uniform distribution. Efficient coagulation of fines, yeast cells and debris follows, and at the same time the very gentle shearing action of the mixer enhances the flocculation/coagulation process with minimum protein breakdown.

Occasionally, dependent upon solids loading in the beer, a perlite/kieselguhr suspension is injected through a further Statiflo Motionless Mixer as a filtration body aid.

After the filtration stage, the now bright beer has its final specific gravity adjusted by dilution with cold water. This is a critical application as duty is payable based on final alcohol content.

Cold dilution water is injected into the bright beer at the inlet of a Statiflo Motionless Mixer where thorough and complete mixing takes place. A densometer, positioned at the mixer outlet continuously monitors the bright beer density and, via a simple process control loop varies the cold dilution water injection rate, to ensure very accurate monitoring and control of the final density/alcohol content.

Prior to bottling, the carbon dioxide concentration of the bright beer must be increased by using a Statiflo Motionless Mixer. As with wort aeration, the carbonation process is significantly enhanced by generating the fine gas bubbles which are maintained and uniformly dispersed for a given time interval. A Statiflo Motionless Mixer provides the ideal combination.

The final beer is then processed for bottling, canning and kegging.

The above provides a reliable and high level consistency of process control unmatched by any other item of process equipment. Such high levels of process ensure exactly the right amount of dosed component is injected to eliminate both over and under dosing and help provide optimum quality of final product.

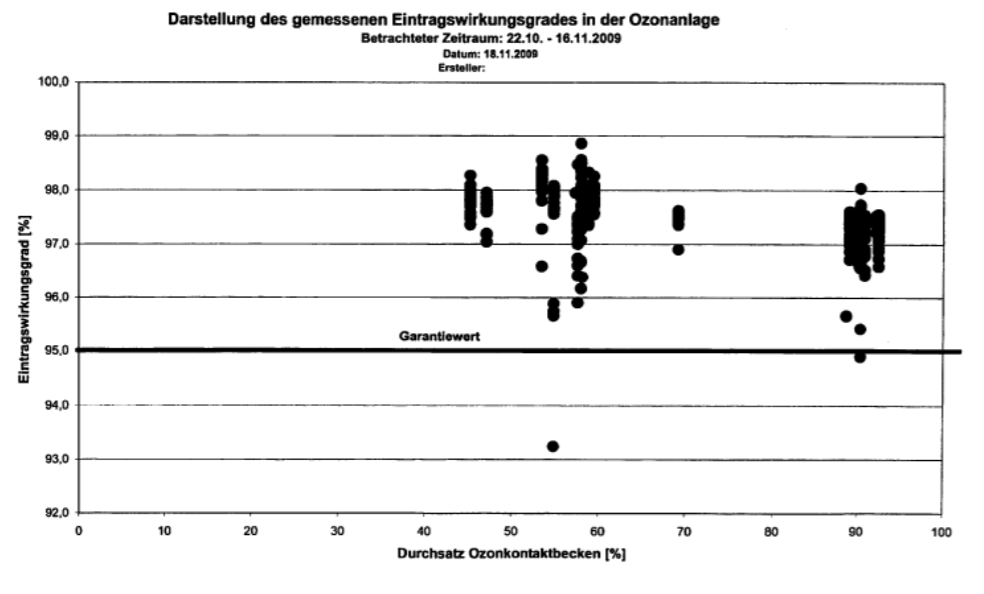

Gas dispersion system for the ozonation of drinking water

Gas Dispersion System: The inline dispersion of a gas in a large volume of liquid very often requires relatively expensive equipment. A classic example is the ozonation of drinking water.…

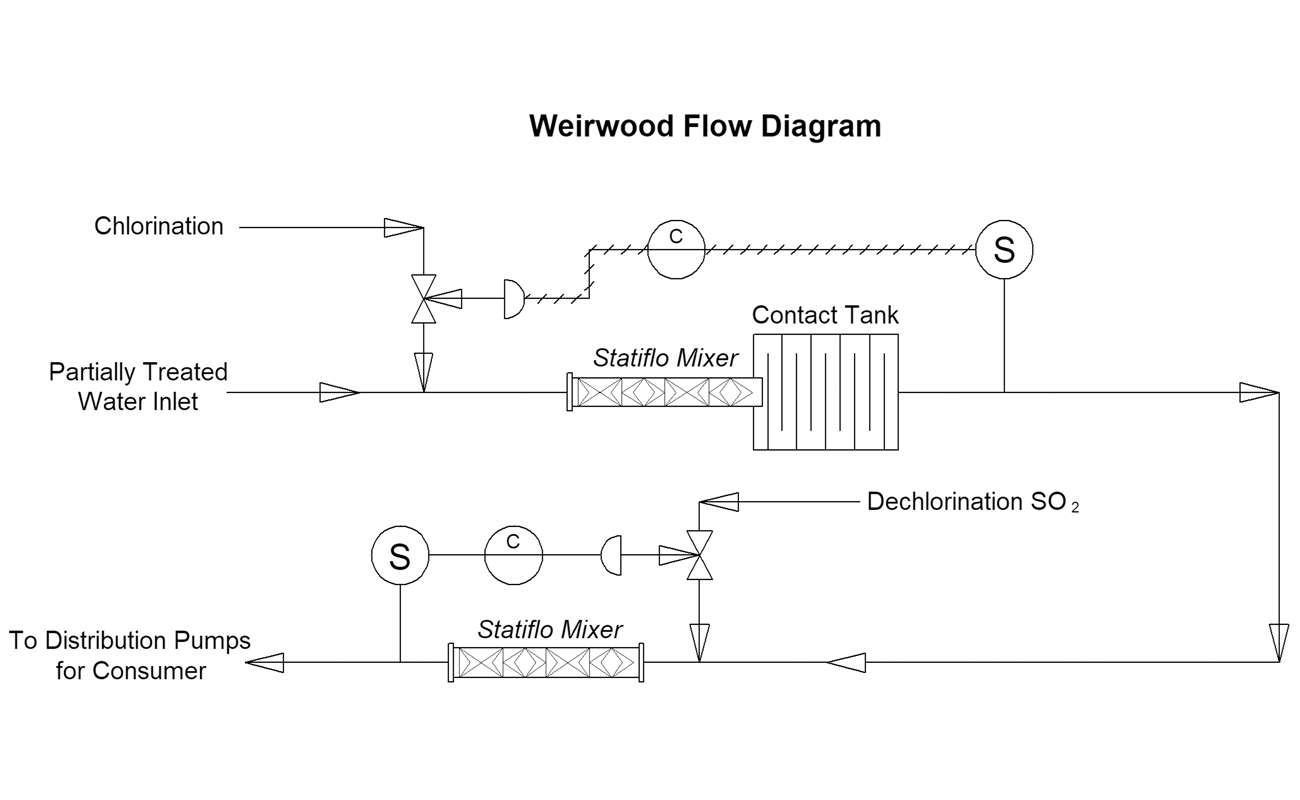

Dechlorination & pH Trim

Problem Dechlorination & pH Trim: Public water treatment plant required highly effective control to dechlorinate and pH trim in difficult access situation. Southern Water’s Weirwood Treatment Works supplies direct to…

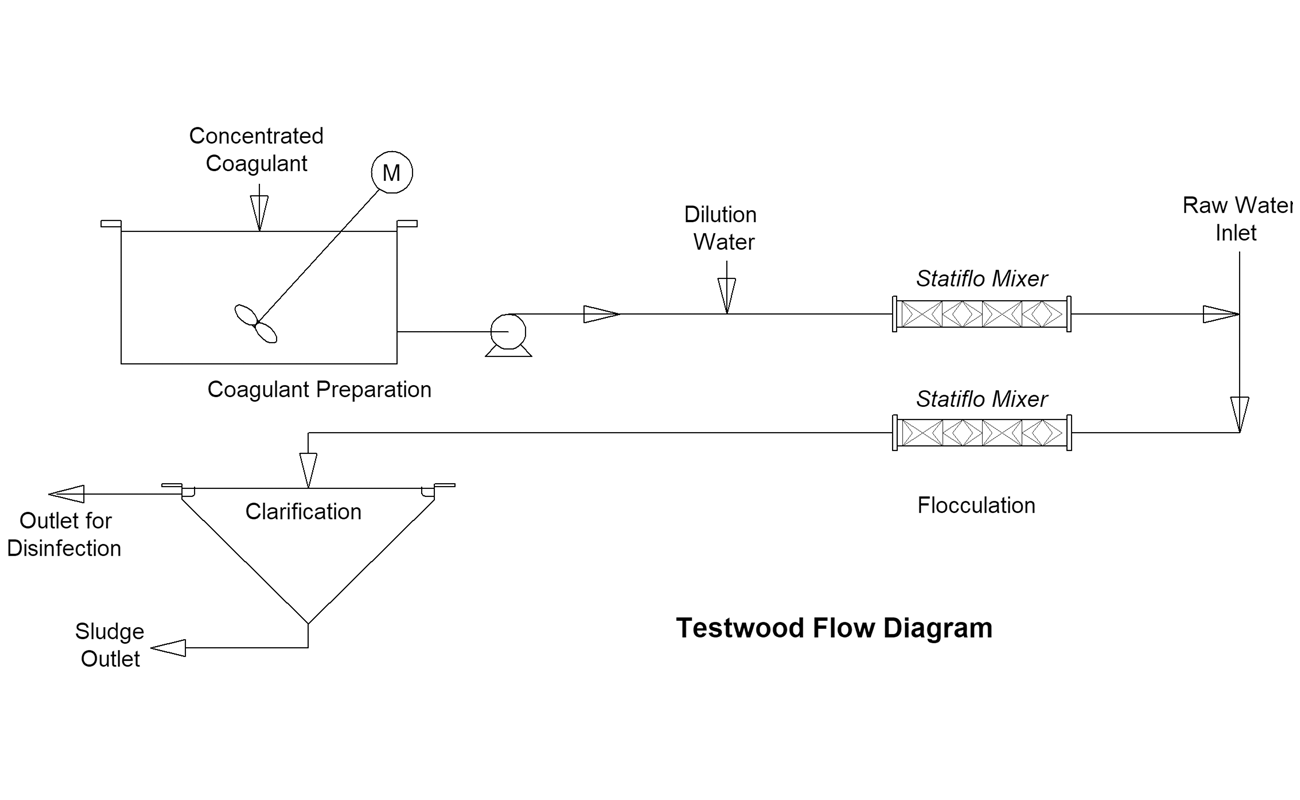

Disinfection of Drinking Water

Problem Effective disinfection of drinking water supplies is essential for safe operation. Relying on natural turbulence alone in a pipeline will not guarantee complete mixing of injected sidestream at all…

Replacing Inefficient Dynamic Mixer

Problem As part of their policy of constant improvement and updating, Southern Water had identified that an opportunity existed to improve consistency of performance, energy consumption and maintenance costs at…

Related Products

Hygienic/Sanitary Static Mixer (Series 200)

Sanitary Mixer: Sanitary and hygienic design Inline Static Mixers with removable elements suitable for use in food & drink, brewery…

General Industrial Static Mixer (Series 100/150)

Statiflo General Industrial Inline Static Mixers suitable for all process industries supplied with fixed or removable mixing elements. Usually supplied…

Steam Heater/Direct Steam Injection Static Mixer (Series 800/850)

Direct steam heaters in steel and exotic alloys for all industries. Fixed elements with integral steam injector or injector jacket.…

S-Type Static Mixer (Available in stock)

Statiflo Inline Static Mixers suitable for all process industries. Pre-fabricated and packed - meaning you can have rapid delivery of…