The Environmental Benefits Of Static Mixers In Wastewater Treatment Wastewater treatment plants play a critical…

Static Mixers Vs Dynamic Mixers: Which Is Right For Your Process?

In many industrial applications, including food processing, water and wastewater treatment, desalination, paper production, and general chemical processing, blending and mixing fluids is critical for optimal results. Static mixers and dynamic mixers are the two principal mixing machinery options available to process engineers and both can be used to achieve the same mixture quality, or mixing goal. But what are the pros and cons of each? In this article, we’ll explore the differences between static and dynamic mixers and their advantages and disadvantages.

Static Mixer Design

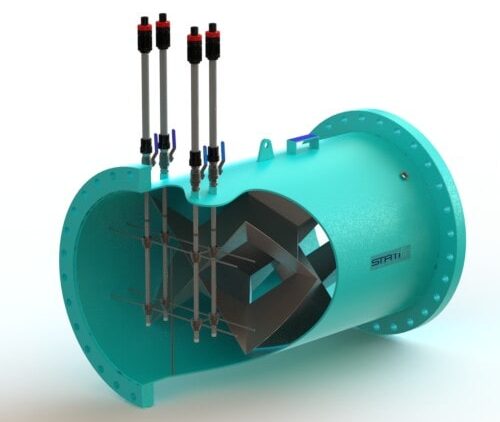

Static Mixer Design

A static mixer is an immobile unit that includes stationary elements such as baffles, blades, or elements arranged in a specific pattern within the pipe or tube. These elements cause the fluid to divide and recombine, resulting in increased levels of turbulence and mixing in a continuous flow, without the need for any moving parts or external power source. This is the principal difference between a static and dynamic mixer.

Advantages And Applications

Static mixers typically have a lower cost than dynamic mixers and can be installed easily as they require no external power source.

Static mixing has several advantages over dynamic mixing, including:

- Cost-effectiveness.

- Low maintenance requirements and good reliability.

- Low energy consumption and operating costs due to having no moving parts.

- Requires a lower footprint.

- Ease of installation.

Dynamic Mixer Design

In contrast to static mixing machines, dynamic mixers require electrical power input to create turbulence and mixing within the fluid. The mixers use a rotating shaft and impellers to blend liquid components, often spinning at high speed. However, faster rotation can also have negative consequences when incorporating shear-sensitive chemicals such as coagulants and flocculants. Dynamic mixers also typically require more space and inspection points for installation, increasing the complexity and cost of installation.

Advantages And Applications

Dynamic mixers are ideal for batch blending high-viscosity fluids or when a homogenous mixture is required in a tank.

Therefore, their primary advantages are:

- Can provide high shear mixing.

- Variable operating speed.

- Lots of different impeller designs are

Factors To Consider

When choosing between static and dynamic mixers, several factors must be considered. These include viscosity, the density of the fluid, the desired mixing quality, throughput requirements, installation length, and flow rate of the reactants.

Enquire Now

Both static and dynamic mixers have their advantages and drawbacks, and the choice between them depends on your specific application. Although static mixers are generally less complicated and have a lower cost of ownership, they may not be suitable for every application, so ultimately, the choice between static and dynamic mixers relies on personal preference, knowledge, and experience when dealing with different processes.

If you’d like to discuss your requirements with one of our experienced engineers and find out more about our industry-leading range of static mixing equipment, please contact us today.

Image Source (Within-text image): Canva