Static Mixers Vs Dynamic Mixers: Which Is Right For Your Process? In many industrial applications,…

Statiflo were approached by a major contractor working in the North Sea who encountered a problem where accurate sampling for fiscal metering was required across turndown of 8:1 over the well life. The process could accept a maximum pressure drop of just 0.2 bar.

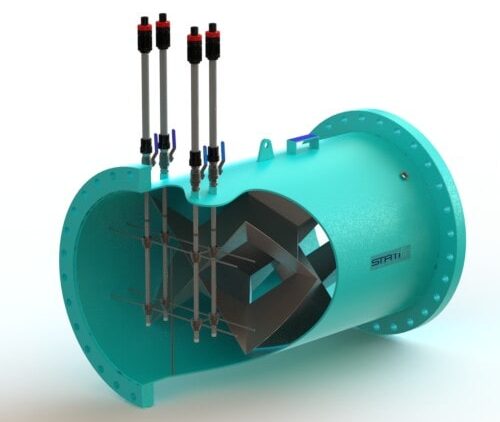

Statiflo’s Engineers worked closely with the contractor and end user to develop an inline static mixer which could easily be adapted to achieve a C1/C2 ratio ratio of the distribution of water particles across the pipeline)in line with the requirements of ISO3171 over the complete flow range, without exceeding the maximum acceptable pressure drop. The existing pipework was 6”NB and Statiflo’s Engineers determined that to meet the requirements the flow would need to be through 4”, then 3” and finally 2”NB static mixers.To ensure there were no changes to the installed pipework, Statiflo developed a system using a single 6”NB spool with easily removable 4”, 3” and 2”NB static mixer inserts. Each insert would include Statiflo static mixing elements, designed to fit within a machined seat within the 6”NB spool.

Statiflo Duplex Static Mixers

Statiflo received the contract for these and the 3 off further Duplex static mixers required within this project.

For further information on this story please contact [email protected]

Inline Static MixerMixing in Wastewater TreatmentStatic Mixer Water TreatmentStatic MixersWaste Water Tank MixersWastewater AgitatorWastewater Treatment MixersWastewater Treatment Plant MixersWater Treatment Mixers