Statiflo Supply Inline Static Mixers to the Pulp and Paper Industry

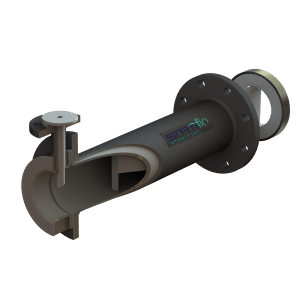

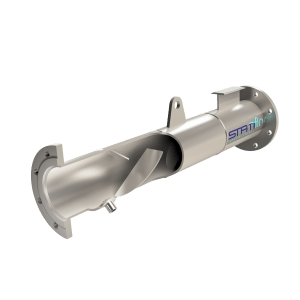

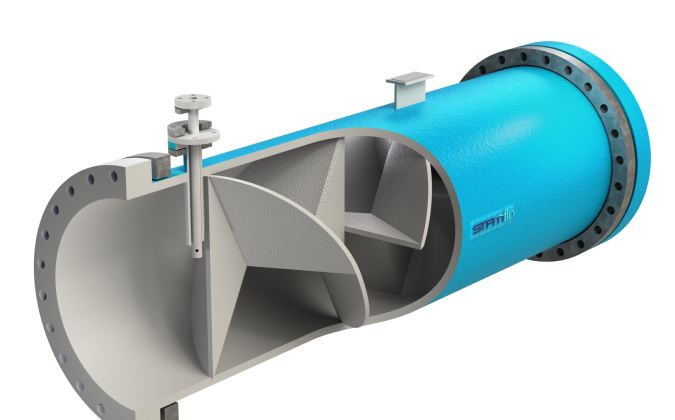

Statiflo are recognised as key suppliers to the Pulp & Paper Industry, supplying Static Mixers – sometimes known as Inline Static Mixers, Static Mixers or Motionless Mixers – to blue chip companies in this industry.

The Pulp and Paper industries require a high quality product in order to maximise time between shutdowns and prevent any risk of unscheduled dowtime.

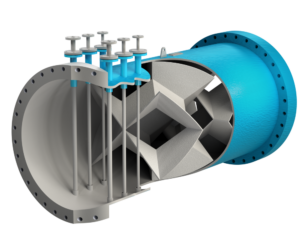

Statiflo Static Mixers for the pulp and paper industries are energy saving compared to mechanical mixing equipment, provide chemical savings to meet strict environmental controls along with providing a continuous and constant mixture quality over a wide range of throughputs.

With a range of mixers manufactured in stainless steel, PTFE, Alloy 20, Hastelloys, Titanium and FRP/GRP. With this range of materials they are ideally suited to applications such as:-

- Acid dilution, caustic dilution and pH control.

- Stock dilution.

- Stock blending, for both new and recycled products.

- Chemical, filler and additive blending

- Low consistency bleaching

- Green liquor coagulant addition.

- Stock bleaching.

- Overall length can be varied to suit space limitations.

- Element geometry can be designed for both high and low head loss systems.

- Large diameter – no theoretical upper limits.

- Elements for rectangular or other unusually shaped ducts and open channels

- Special designs for incorporating in bends, offer space saving and minimal disturbance to piping systems.

- Guaranteed highly efficient mixing.

- No moving parts provide a maintenance free operation.

- Reduction in operational energy costs, as no direct power is required.

- Ease of installation.

- Minimal space requirements with no upstream or downstream pipe lengths required. Providing short control process times in applications where quick process response control is critical.

- Short process chemical dosing control loops provide optimum performance in response to rapidly changing process conditions, as well as reducing chemical costs.

- Available in a wide ranges of sizes and material to suit most applications.

- Each unit is custom designed benefiting from Statiflo’s long term experience in designing and manufacturing static mixers to the highest of standards.

- Total support is provided by highly trained engineers situated in Statiflo regional country offices and a world wide representative network.

Application Examples

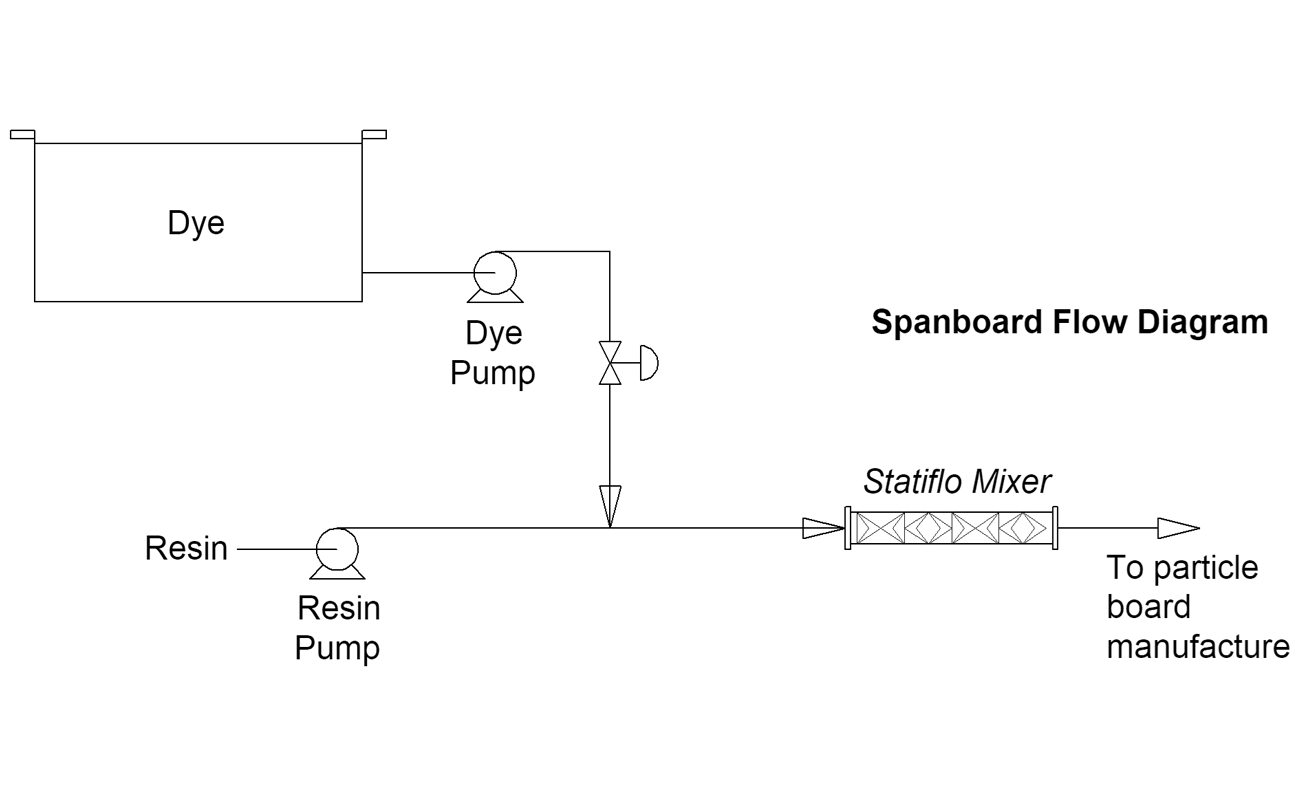

Costly overdosing of dye in colour coded particle board manufacture resulted in unnecessary loss of profit. Spanboard, manufacturers of multigrade woodchip particle board, used colour coding for grade identification.

The colouring was achieved by the addition of dye to the resin which bound the woodchip particles. It was suspected that overdosing was inadvertently being used to compensate for poor mixing due to the high viscosity of the resin and laminar flow.

Upon further investigation it was confirm that excessive dye dosing was indeed taking place as a means of compensating for poor mixing and Statiflo recommended the installation of a 25mm diameter 6 element Motionless Mixer at the dye injection point.

As a result a dramatic reduction in dye ensued. The Statiflo Inline Static Mixer which cost less than £300 resulted in a first year saving of £44,000 on dye costs – a payment time of less than 2 and a half days.

For further information please see case study.

Overdosing of Expensive Dye in Viscous Resin

Problem Overdosing of Expensive Dye in Viscous Resin: Costly overdosing of dye in colour coded particle board manufacture resulted in unnecessary loss of profit. Spanboard, manufacturers of multigrade woodchip particle…

Related Products

GRP/FRP Static Mixer (Series 500/550)

Corrosion resistant GRP/FRP, large diameter (+250mm) mixers with fixed elements for corrosive applications in the water, wastewater, desalination and pulp…

General Industrial Static Mixer (Series 100/150)

Statiflo General Industrial Inline Static Mixers suitable for all process industries supplied with fixed or removable mixing elements. Usually supplied…

PTFE Corrosion Resistant Static Mixer (Series 300)

Static Inline Mixers with solid PTFE removable mixing elements and PTFE lined carbon steel housing for corrosive duties in all…

Non-Ragging Pipe Mixer

The Statiflo Non-Ragging (NR) Pipe Mixer - also called a Non-Blocking or Non-Clogging Static Mixer - is a high performance…