Oil, Gas & Petrochemical Industries

The Petrochemical, oil and gas industries incorporate a number of processes where static mixers play an important part such as stream blending, additive mixing, liquid dispersion, emulsion formation, chemical reactors, laminar-flow heat transfer, mass transfer, and custody transfer/fiscal measurement.

The reason that static mixers are popular in these applications are that they provide highly efficient mixing with no moving parts and are therefore maintenance free, at the same time providing significant cost savings as no direct power is required. Minimal space is required, installation is quick and easy and they are available in a variety of materials to suit the application.

Providing mixing in a uniform volume, they are ideal for when reactions are taking place which are critical to product purity. For multiphase systems high energy dispersion rates and an even shear history help to improve mass transfer.

Typically these industries require a high level of QA/QC and as Statiflo operate with the latest ISO Quality Management Systems we can provide you with the documentation you need to meet your requirements. Example documentation in addition to the General Arrangement drawings supplied as standard with every order would include NDT procedures/reports, 3.1 or 3.2 material certificates, Quality Plan/Inspection Test Plan, Production Schedule, WPS/PQRs and a Certificate of Confirmity. Other documentation is avaialbale upon request.

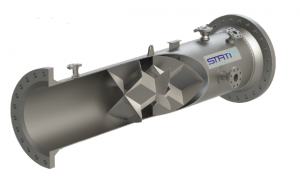

Statiflo have a wide range of pipe and channel static mixer designs. Each mixer and the number of elements is carefully selected and designed by our engineers based upon proven design principles that have been independently tested and verified.

Statiflo is known throughout the world as a recognised supplier for the Oil, Gas and Petroleum industries.

Below you can find some brief details of applications which we have supplied static mixers for but to find out more about your application, contact us today.

In assessing the benefits of Statiflo Inline Static Mixers it is important to remember:

- Overall length can be varied to suit space limitations.

- Element geometry can be designed for both high and low head loss systems.

- Large diameter – no theoretical upper limits.

- Elements for rectangular or other unusually shaped ducts and open channels

- Special designs for incorporating in bends, offer space saving and minimal disturbance to piping systems.

- Guaranteed highly efficient mixing.

- No moving parts provide a maintenance free operation.

- Reduction in operational energy costs, as no direct power is required.

- Ease of installation.

- Minimal space requirements with no upstream or downstream pipe lengths required. Providing short control process times in applications where quick process response control is critical.

- Short process chemical dosing control loops provide optimum performance in response to rapidly changing process conditions, as well as reducing chemical costs.

- Available in a wide ranges of sizes and material to suit most applications.

- Each unit is custom designed benefiting from Statiflo’s long term experience in designing and manufacturing static mixers to the highest of standards.

- Total support is provided by highly trained engineers situated in Statiflo regional country offices and a world wide representative network.

Application Examples and Case Studies

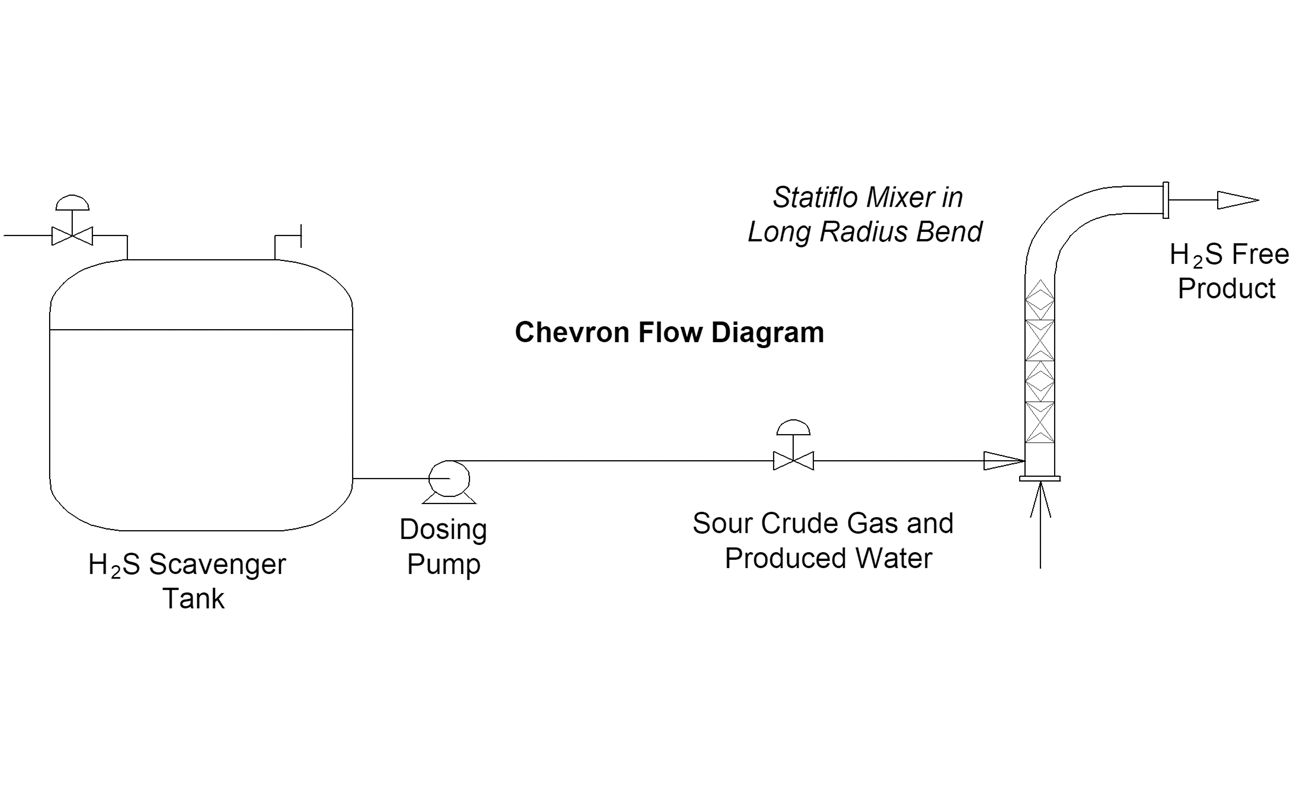

Hydrogen Sulphide contamination of crude oil can threaten closure of a well head. Statiflo mixers have been used when scavenging agents have been introduced at the well head to de-sour the crude oil before contact with any of the plant.

The Statiflo mixers are required to:

Provide thorough mixing to ensure neither the scavenging agent nor the hydrogen sulphide remained resident beyond the flowline.

operate at a very high pressure (c350bar)

be corrosion resistant

operate in a confined space

To meet these requirements Statiflo designed an extra strong corrosion resistant alloy Hastelloy C276 with three element mixer. Additional high pressure quick release end connections conforming to oil industry standards.

For further information see case study.

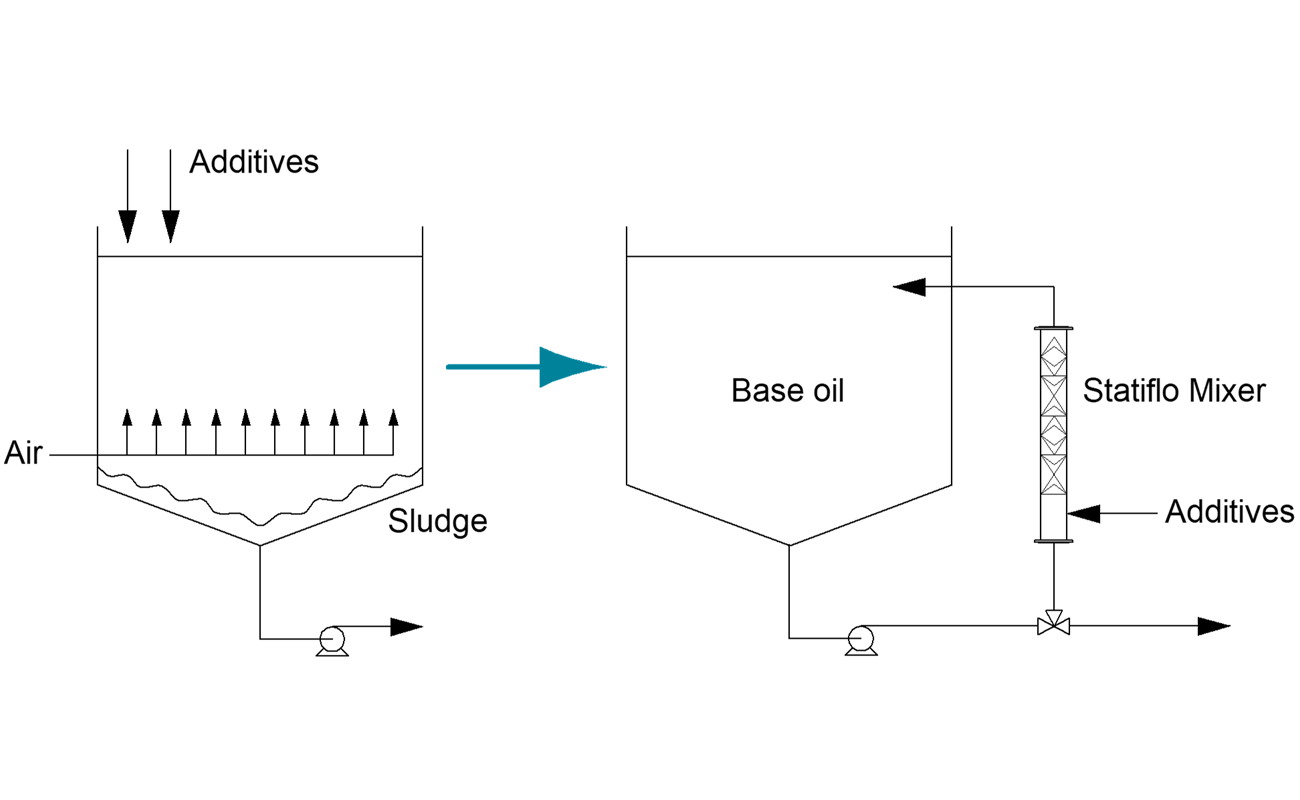

Certain designs of tank blending systems can lead to excessive energy consumption to poor product quality control.

Statiflo recommended that a dedicated transfer pump should be used to provide energy for mixing using a Statiflo motionless mixer installed in a recycling line. Additives being injected at the mixer for optimum effect.

The end result was that mixing times were reduced from several days to approximately 16 hours. Compressed air was no longer required for mixing and oxidation of the base oil eliminated. The air sparge pipe system was removed from the tank and equipment elsewhere on the plant was no longer starved of compressor air. The sludge buildup was stopped because of improved mixing and lack of overdosing. This was also helped by the pumping the recycling stream from the tank bottom.

Following this success a further nine tanks were converted and each provided with a Statiflo motionless mixer.

For further information see case study.

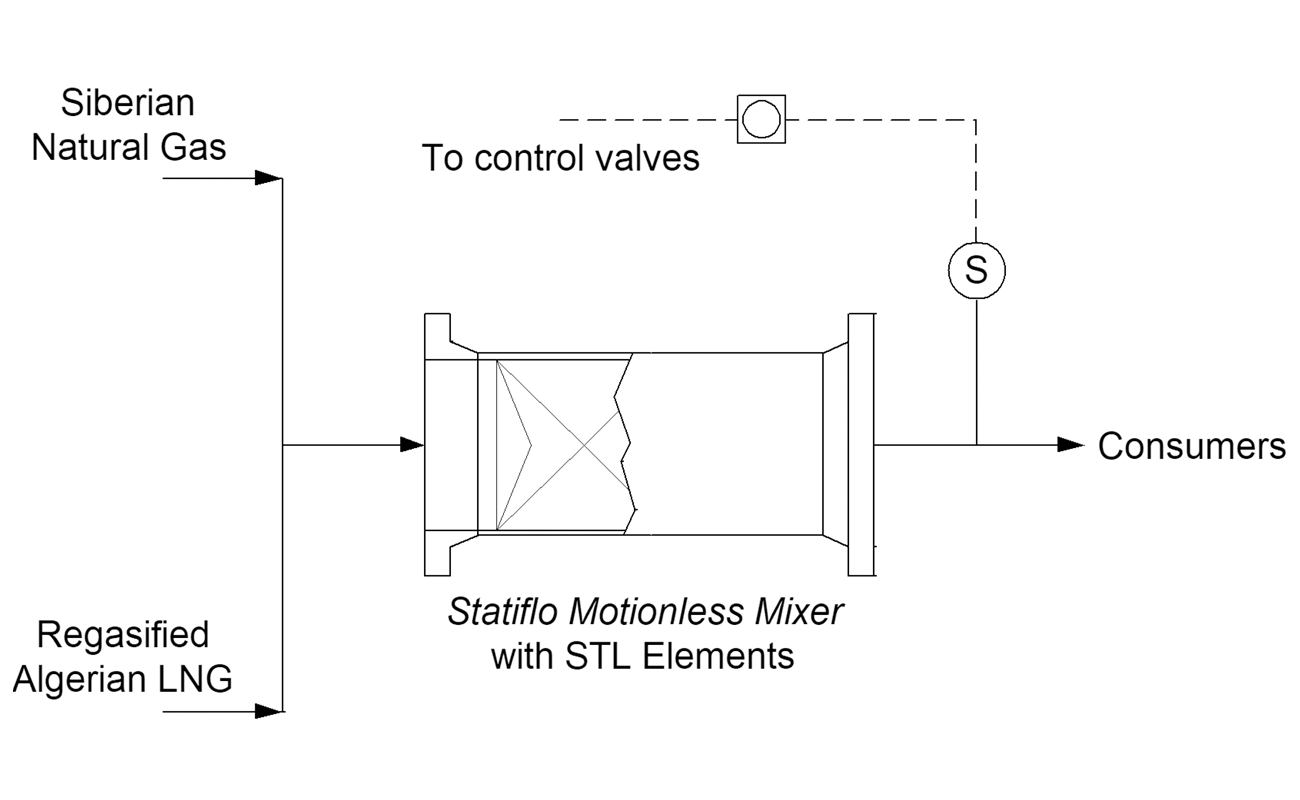

Mixing of two different types of natural gas in a large diameter pipeline is not straightforward despite the high velocity, high turbulence and low viscosities. Relying on natural turbulence in along pipe for mixing results in unrepresentative sampling and long time lags in the control system. Good and fast mixing are essential for continuously monitoring and controlling the net heating value of the gas mixture.

In one particular instance two Statiflo motionless mixers were chosen for installation at a gas mixing station on a major gas transmission system. The parallel lines were 900mm diameter, operating at 32 bar g for mixing Siberian natural gas with regasified Algerian LNG. The mixers were designed for use in a high velocity, highly turbulent service.

The end result is that Athens area consumers now rely on Statiflo motionless mixer technology for the continuous monitoring and control of Net Heating Value of natural gas in their city. The equipment is simple, safe, reliable, without moving parts, requiring no maintenance and is ideally suited for a hazardous duty.

For further information see case study.

It is of the utmost importance that seller and customer both know exactly the water content of the oil they are purchasing or selling. This can often be very difficult because the best sampling systems in the world can only provide accurate data if they are taking a representative sample.

Statiflo’s market-leading dual leading edge designs can consistently achieve a C1/C2 ratio above 0.9, in accordance with ISO3171 and API 8.2 standards, therefore meaning that the water is adequately dispersed within the oil and that a representative sample can be taken at the mixer discharge for water in oil analysis.

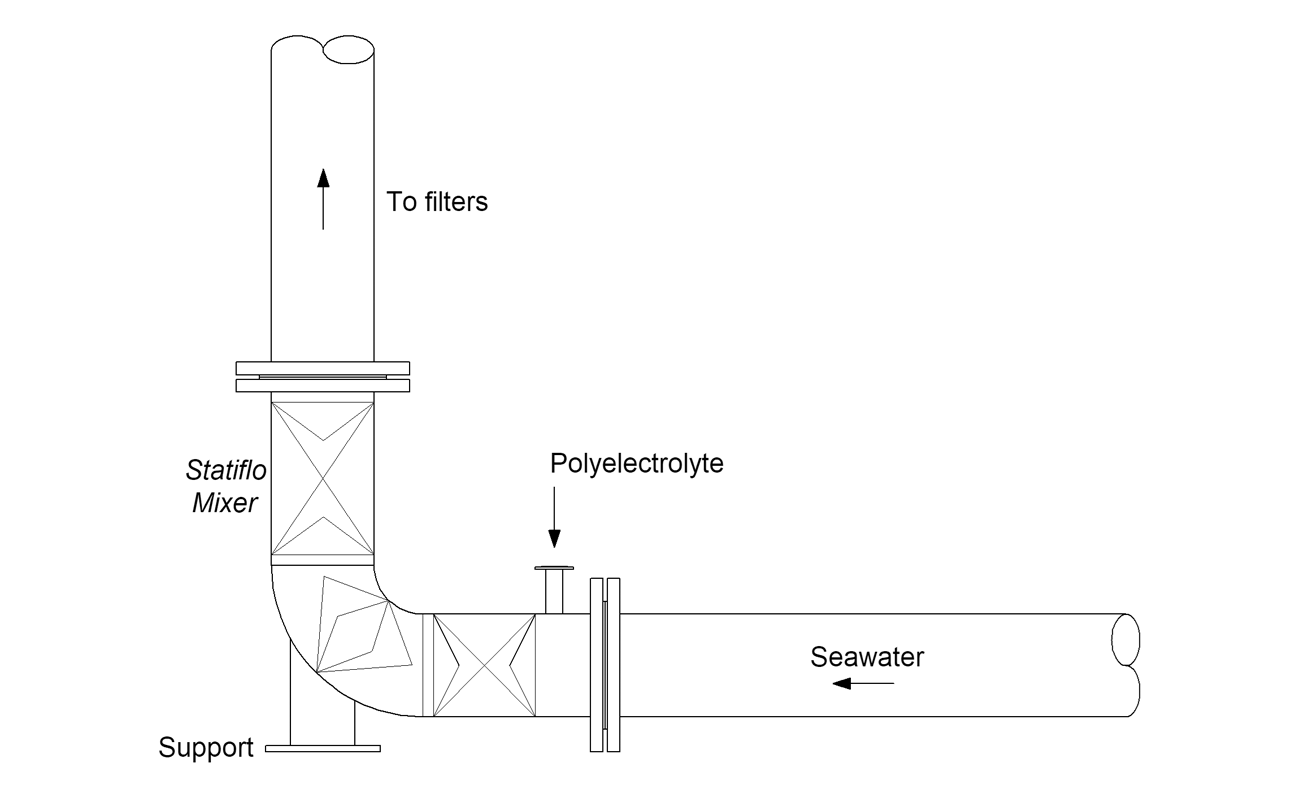

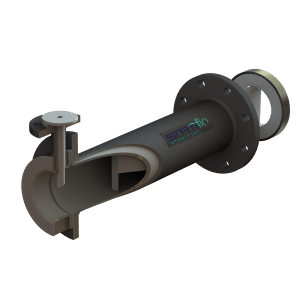

On some platforms, sea water is filtered to high pressure injection on secondary recovery systems. Chemical injection points were upstream of the filters to improve their performance.

In one particular instants a Statiflo mixer in cupro-nickel was customer designed to fit into a very tight space. There was a pipe section comprising a very short length of and a long radius 900 elbow on the manifold inlet. A custom designed mixer with mixing elements fitted in both the straight and curved piping. There was even space for an integral polyelectrolyte injector – all within existing dimensions. Much to the relief of the contractor, expensive resiting of the pump and/or filters was avoided.

This special design ensured that each filter received the same dose of polyelectrolyte. The low shear mixing action avoided rupture of the long chain molecules, allowing minimum dosing rates of the expensive additive.

For further information see case study.

A contractor working on a heavy upgrading project in Korea, required a cost effective method of intimately contacting a two phase gas /liquid system. Expensive large diameter towers with complex internal packing were considered to be unsuitable because of the very corrosive nature of the fluids and the high operating pressures. Contacting would have to be equally effective under two operating conditions; normal operation and regeneration system.

Statiflo were approached to design an online Motionless mixer with diameter identical to the contacting 26” pipe, suitable for operation at 175 kg/cm2 G & full vacuum at 165oC. High pressure flanges were required with internal mixing elements specified in Incoloy 800. Mixing housing was to have Incoloy 800 overlay on carbon steel.

Due to the high operating pressure and very corrosive service, rigorous quality control and testing were essential.

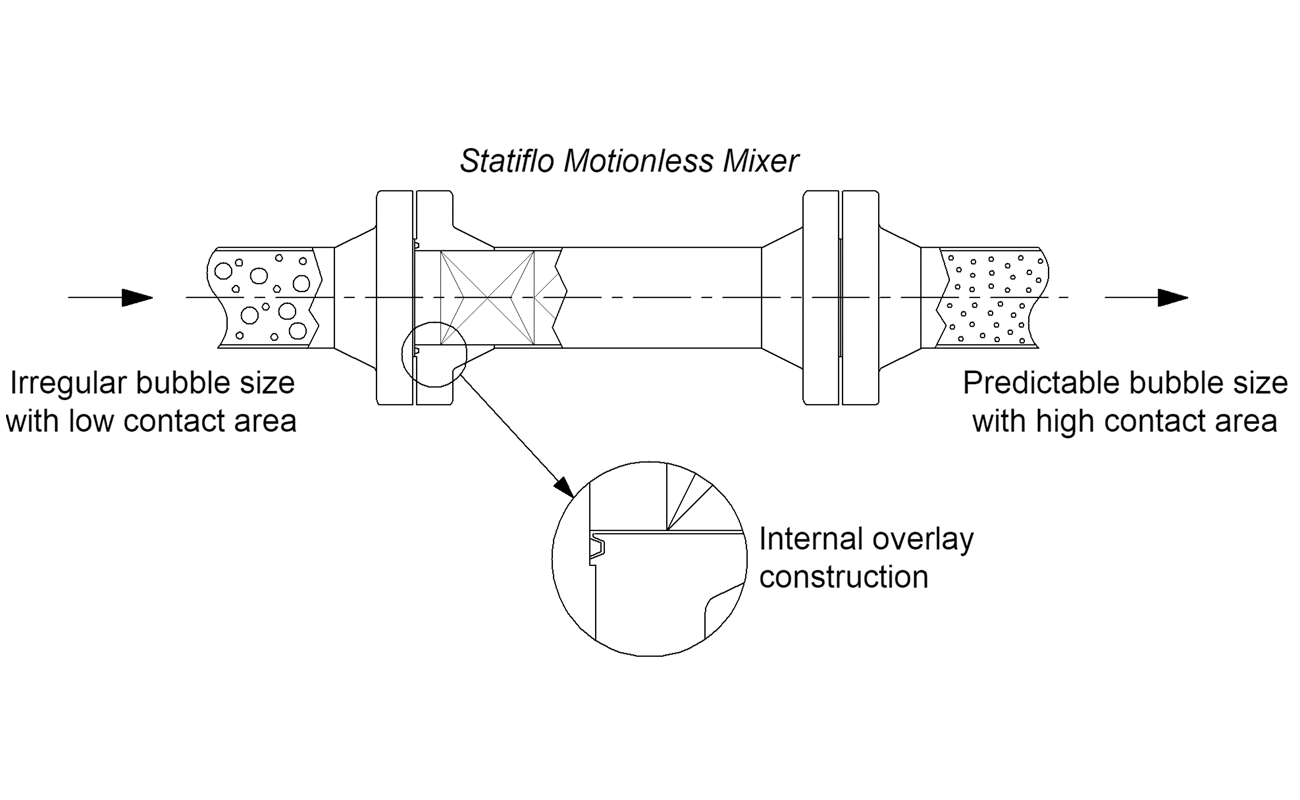

The end result was that that ideal plug flow characteristics and intense radial mixing in the mixer resulted in a predictable and narrow droplet size of liquid in gas. Contacting was optimised in a relatively low cost inline design in corrosion resistant construction. Energy consumption, in terms of pressure drop, was extremely low and well within the capabilities of the pumping systems.

For further information see case study.

Gas/Liquid Turbulent Mixing

Problem Gas/Liquid Turbulent Mixing: A Japanese contractor, working on a heavy oil upgrading project in Korea, required a cost effective method of intimately contacting a two phase gas / liquid…

Gas/Gas Turbulent Mixing

Problem Gas/Gas Turbulent Mixing: Mixing of two different types of natural gas in a large diameter pipeline is not straightforward despite the high velocity, high turbulence and low viscosities. Relying…

Improved Tank Blending

Problem A lube oil blending plant in the north west of England was experiencing a whole host of problems with its existing tank mixing system, ranging from excessive energy consumption…

Space Saving – Mixer in Bend

Problem Sea water is filtered prior to high pressure injection on secondary recovery systems. A North Sea platform had been designed and partially built with three large filters operating in…

Hydrogen Sulphide Contamination of Crude Oil

Problem Hydrogen sulphide contamination of crude oil threatened closure to a well head on one of the Chevron UK operated Ninian North Sea oil platforms owing to resultant H2S gas…

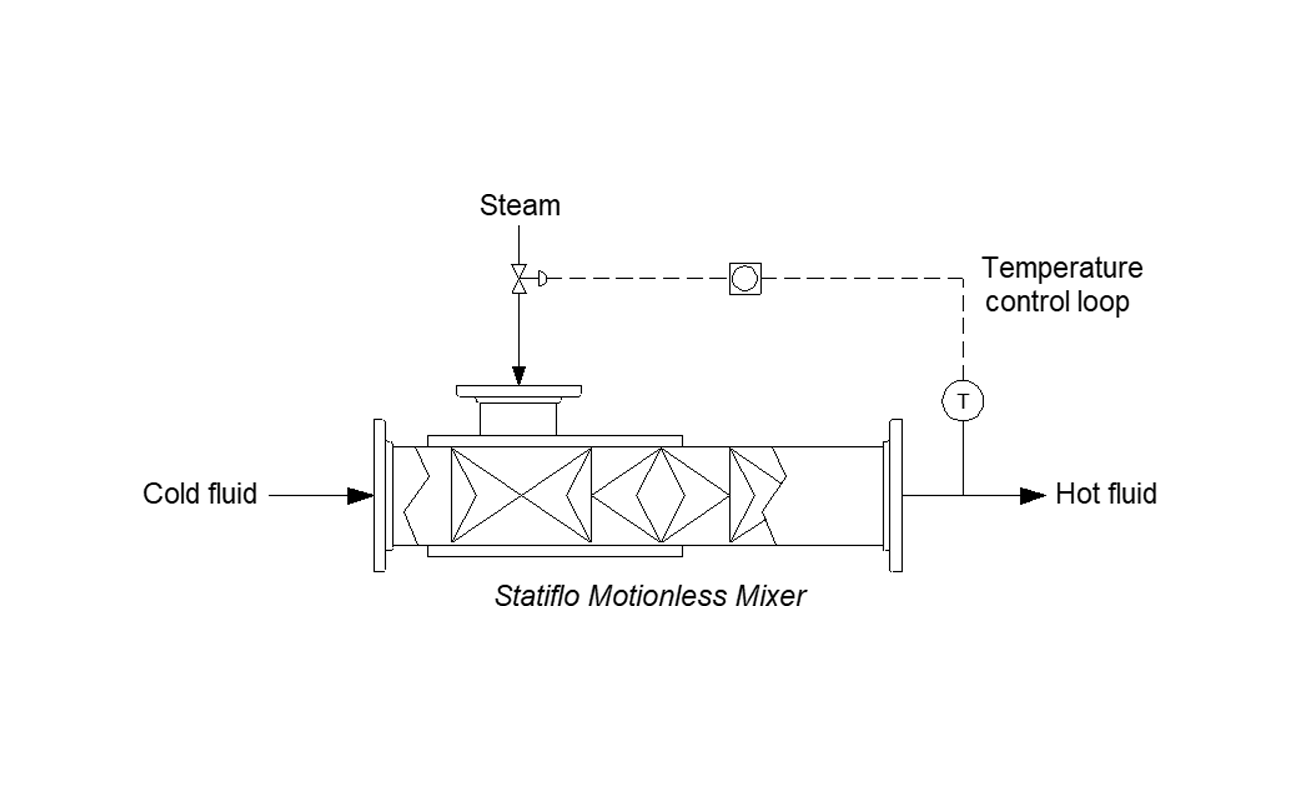

Direct Steam Injection / Heating

Problem Direct Steam Injection / Heating: How is it possible to optimise the temperature of washwater used for cooling and removing trace contaminants from fibres during the final stages of…

Related Products

Custody Transfer Mixers

Statiflo Series 100/150CT Custody Transfer Motionless Mixers are designed to be versatile enough to cover all your custody transfer applications…

General Industrial Static Mixer (Series 100/150)

Statiflo General Industrial Inline Static Mixers suitable for all process industries supplied with fixed or removable mixing elements. Usually supplied…

PTFE Corrosion Resistant Static Mixer (Series 300)

Static Inline Mixers with solid PTFE removable mixing elements and PTFE lined carbon steel housing for corrosive duties in all…

Customers Include