Problem

Manufacturers of a world famous cosmetic cream were faced with an unexpected problem just days before a new facility was due on full scale production. The filling operation was unable to satisfactorily fill the jars. Due to the higher than anticipated cream viscosity, air spaces were forming in the bottom corners of the containers. Although the correct weight of cream was being dispensed, consumer trials indicated that customers were unhappy with the appearance of the product in the jar.

Solution

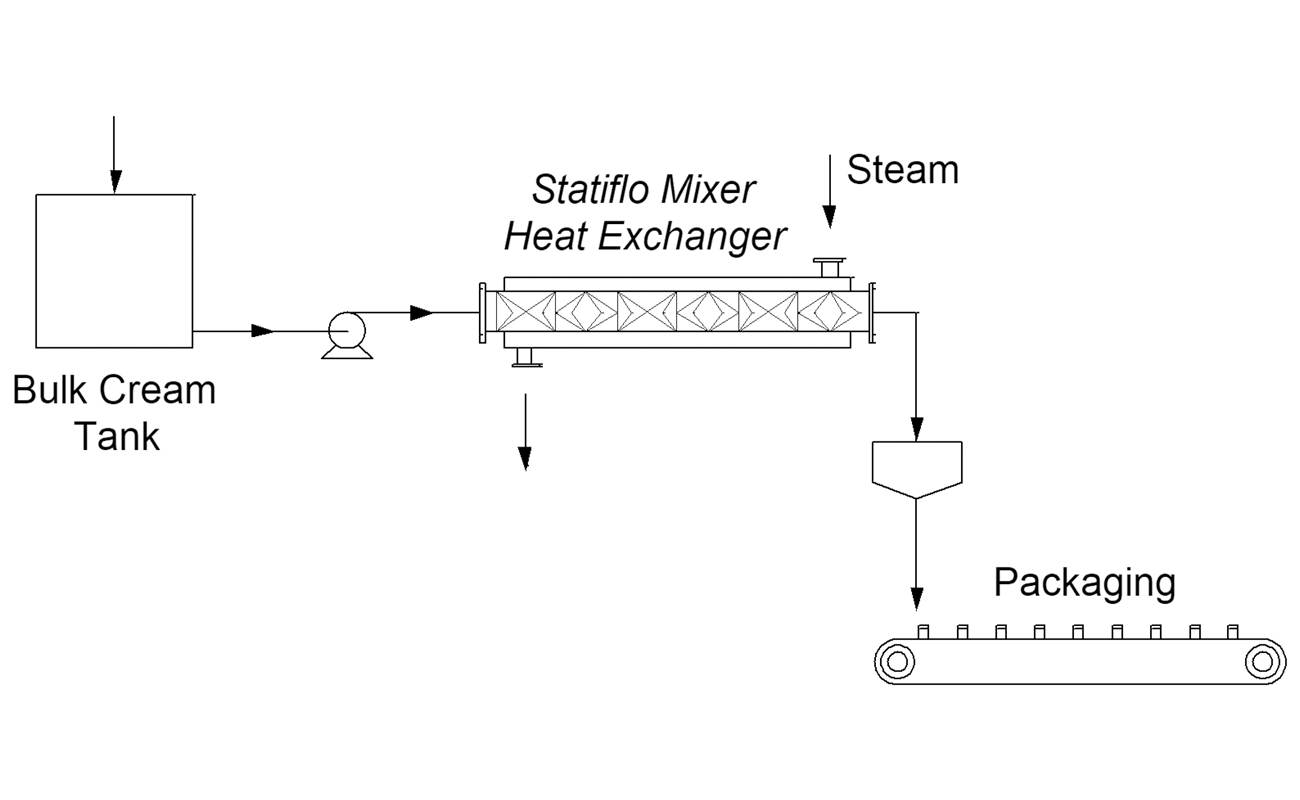

The manufacturer’s engineers quickly determined that the high viscosity of the cream was responsible for poor flow into the jars. Heating the cream would reduce the viscosity, but there was serious concern because the cream was heat sensitive. Conventional heating methods were ruled out because of the high viscosity, laminar flow condition and the certainty of developing hot spots.

Statiflo was approached to design a custom engineered Mixer / Heat Exchanger based on the Series 200 range of sanitary units with removable elements and incorporating a steam heating jacket. A short delivery was vital – full scale production was scheduled to commence in less than two weeks.

The radial mixing action of the Statiflo Motionless Mixer is responsible for the elimination of internal film boundaries which are the biggest resistances to efficient heat transfer in laminar flow. Intense mixing also prevents hot spots occurring in the heat sensitive cream.

Result

The design of the Statiflo Motionless Mixer / Heat Exchanger was completed in hours and approved shortly afterwards by the customer’s engineers. Despite the normal eight week delivery period of this complex equipment, Statiflo promised to complete its obligation in ten working days.

The equipment arrived at its overseas site two days early. Installation was very straightforward and immediately solved the problem – and well in time to meet the scheduled date for full scale production.

The cream exited the Statiflo equipment at a controlled elevated temperature and reduced viscosity. Flow into the jars was improved sufficiently to completely eliminate the unsightly air spaces. The customer was happy knowing that full production had not been delayed and adverse user reaction had been averted.

- No moving parts for maintenance free operation

- Sanitary design in polished stainless steel

- Suitable for cleaning in place (CIP) systems

- Extremely simple installation procedures

- Prevents localised overheating and hotspots

- Increases overall heat transfer coefficient by up to 500% compared with empty pipe

- Consistent and predictable performance

- Self cleaning

Other Statiflo Features

- Minimal space requirement

- Completely sealed system

- Self cleaning

- Available in all sizes

- Eliminates radial gradients

- Available in any material

- Custom designed

- Meets all QA/QC levels

- Available worldwide

- Low installed weight