Custody Transfer Mixers (CT Mixers)

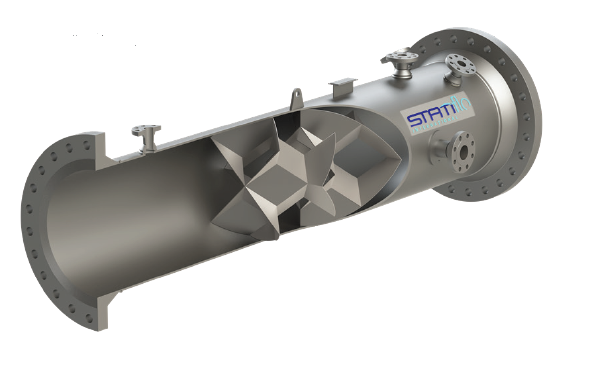

Statiflo Series 100/150CT Custody Transfer Motionless Mixers are designed to be versatile enough to cover all your custody transfer applications including transfer stations, LACT skids, etc.

It is of the utmost importance that seller and customer both know exactly the water content of the oil they are purchasing or selling. This can often be very difficult because even the best sampling systems in the world can only provide accurate data if they are taking a representative sample.

Statiflo’s market-leading dual leading edge designs can consistently achieve a C1/C2 ratio above 0.9, in accordance with ISO3171 and API 8.2 standards, therefore meaning that the water is adequately dispersed within the oil and that a representative sample can be taken at the mixer discharge for water in oil analysis. Return on investment is typically measured in months, not years.

Remember – Statiflo Custody Transfer Mixers have no direct power consumption and since there are no moving parts that means there is no maintenance requirements and no expensive spare parts.

Don’t continue to pay for water at crude oil prices, contact Statiflo today for a quotation to fit your custody transfer requirements.

- Market-leading mixing element designs

Smaller sizes are supplied with fixed STL elements (Series 100). 4″ (DN100) and upwards are supplied with a special type of fixed STM elements, called the STM-CT element. This is a specialist adaptation of our already market-leading STM element design, complete with “scoops” to ensure BS&W content does not stay on the bottom of the pipeline and “notches” to prevent air being trapped in the elements.

The mixing elements are fully welded to the mixer housing to allow for higher than normal flow velocity.

- Available for all pipe sizes

Diameters from as small as DN25 (1″) with no theoretical upper limit.

- Ensure compliance with International Standards

As opposed to regular mixing/blending duties where the Coefficient of Variation is the key measurement criteria for determining the performance of a Statiflo Static Mixer, for Custody Transfer/Fiscal Measurement applications a different criteria is used to quantify the performance of the mixing system.

The ISO3171 and API 8.2 standards give guidance on how to calculate the C1/C2 ratio – ie the concentration of water at the top of the pipe (C1) compared to the concentration of that at the bottom (C2).

A C1/C2 ratio of 0.9 to 1.0 indicates a very good dispersion. A ratio of 0.4 or smaller, however, indicates poor dispersion with a high potential for water stratification.

- Accessories to complement

Available with any number of auxiliary connections – including water injection connection if required. Typically supplied with sample take off connection at the correct locations specified in the ISO 3171 and API standards. Reducers/cones are often supplied to ensure the easiest fit into your pipeline.

- Materials to suit your requirements

Stainless steel, carbon steel, Alloy C276, Dulplex/Super Duplex, Inconel or any other commercially available material to meet your requirements.

- Performance Guarantee

Every Statiflo Custody Transfer Mixer comes with guaranteed performance. Our static mixer designs have been extensively and rigorously tested under industry-realistic conditions to allow us to guarantee the mixing performance and the head loss across the mixer. If required Statiflo can perform CFD simulations for specific conditions.

- Testing Standards

A full visual inspection is carried out on each unit before it leaves our premises, along with a dimensional check and any other testing which is required.

Optional tests available including hydrotest, radiography, magnetic particle inspection (MPI), Dye Penetrant Inspection (DPI), positive material identification (PMI) or ultrasonic testing (UT) are all available.

- Design Codes and Standards

Available design codes include ASME B31.3, ASME VIII div 1, AD2000 Merkblatt, PED2014/68/EU and many others to suit your requirements.

- Complete with Statiflo’s Full Documentation Set

Your Static Inline Mixers will come complete with customised GA Drawing, 3.1 Material Certification, a Certificate of Conformity and one copy of our Installation, Operation and Maintenance Manual.

Other documentation such as NDT procedures/reports, hydrotest reports, Quality Plan/Inspection Test Plan, Production Schedule, WPS/PQRs is typically supplied for mixers with these stringent quality requirements.

- Warranty Period

As standard, Statiflo offers a warranty of 12 months from plant commissioning or 18 months from equipment delivery, whichever is the sooner. Extended warranties can be supplied upon request.

- Spare Parts / Special Tools

Statiflo products have no moving parts there is no requirement for expensive spares or special tools.

- Supervision for Installation and Commissioning

The ‘plug and play’ design means there is no requirement for supervision for installation or commissioning. The extremely simple installation is covered entirely by the Installation, Operation & Maintenance manual supplied with each order.

If you would feel more comfortable having guidance on-site, Statiflo can send one of our highly qualified engineers to guide and supervise the installation to give you the confidence that everything is done correctly.

Downloads

Mixer Sizing Questionnaires

Product Brochures

Application Notes

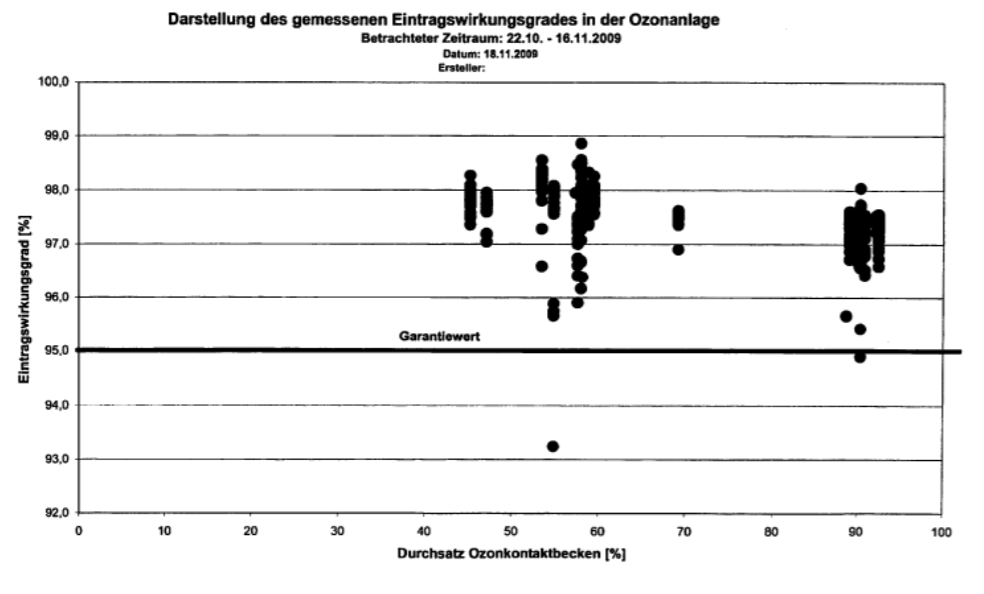

Gas dispersion system for the ozonation of drinking water

Gas Dispersion System: The inline dispersion of a gas in a large volume of liquid…

Case Study

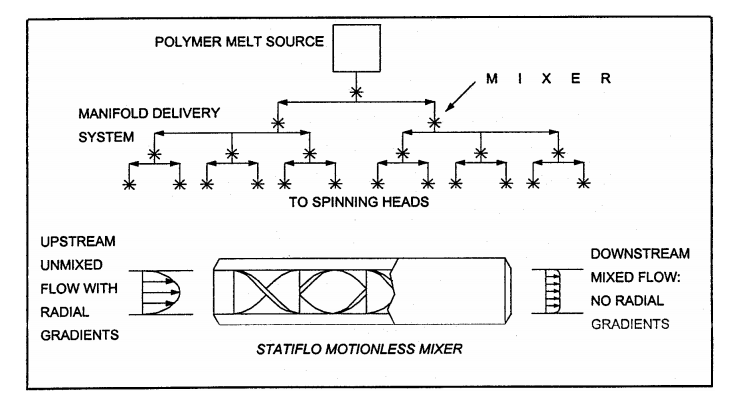

Process with highly viscous polymer melts

Problem A “man-made” fiber spinning plant produces thousands of individual threads simultaneously. All threads come…