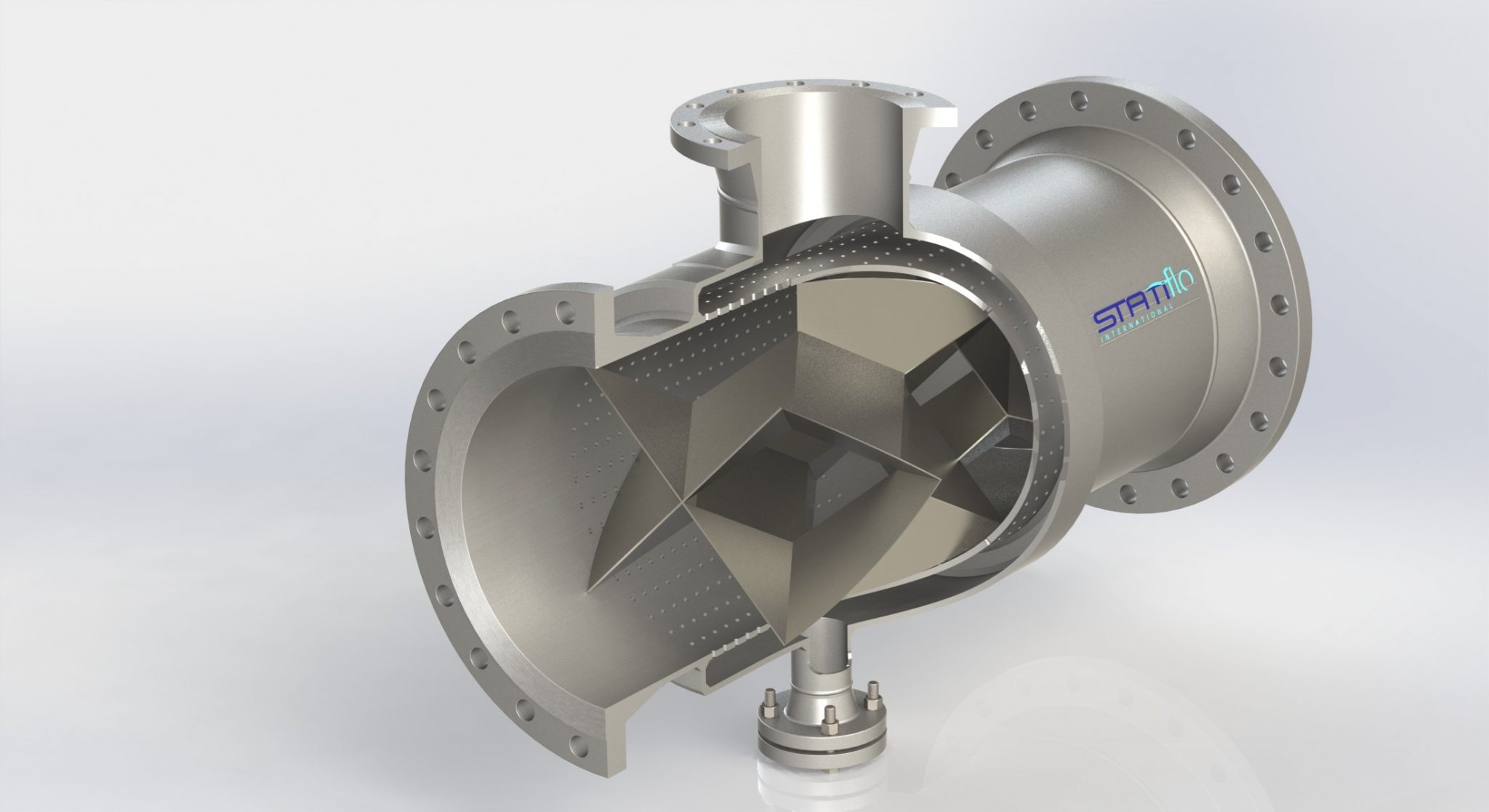

Steam Heater/Direct Steam Injection Static Mixer (Series 800/850)

Direct steam heaters in steel and exotic alloys for all industries. Fixed elements with integral steam injector or injector jacket.

The body of the actual mixer housing would be drilled with a series of steam injection holes to ensure that steam is injected radially around the mixer zone, to enable rapid and uniform dispersion of steam throughout water, resulting in rapid and efficient thermal heating.

Steam Injection Static Mixer

- Market-leading mixing element designs

Supplied with fixed STL elements (Series 800) or fixed STM elements (Series 850), with adjustable element geometry to meet your specific maximum headloss or maximum overall length requirements.

- Available for all pipe sizes

Diameters from as small as DN25 (1″) with no theoretical upper limit.

- Superior mixture qualities achievable

Designed to achieve rapid and uniform dispersion of steam throughout water – resulting in rapid and efficient thermal heating.

- Materials to suit your requirements

Stainless steel, Alloy C276, Dulplex/Super Duplex, Inconels or any other commercially available material.

- Performance Guarantee

Every Statiflo Series 800/850 Inline Static Mixer comes with guaranteed performance. Our static mixer designs have been extensively and rigorously tested under industry-realistic conditions to allow us to guarantee the mixing performance and the head loss across the mixer. If required Statiflo can perform CFD simulations for specific conditions.

- Testing Standards

A full visual inspection is carried out on each unit before it leaves our premises, along with a dimensional check and any other testing which is required.

Optional tests available including hydrotest, radiography, magnetic particle inspection (MPI), Dye Penetrant Inspection (DPI), positive material identification (PMI) or ultrasonic testing (UT) are all available.

- Design Codes and Standards

Available design codes include ASME B31.3, ASME VIII div 1, AD2000 Merkblatt, PED2014/68/EU and many others to suit your requirements.

- Complete with Statiflo’s Standard Documentation Set

Your Static Inline Mixers will come complete with customised GA Drawing, 3.1 Material Certification, a Certificate of Conformity and one copy of our Installation, Operation and Maintenance Manual.

- Further Documentation Supplied for High Levels of QA

Other optional documentation such as NDT procedures/reports, hydrotest reports, Quality Plan/Inspection Test Plan, Production Schedule, WPS/PQRs is available upon request.

- Warranty Period

As standard, Statiflo offers a warranty of 12 months from plant commissioning or 18 months from equipment delivery, whichever is the sooner. Extended warranties can be supplied upon request.

- Spare Parts / Special Tools

Statiflo products have no moving parts there is no requirement for expensive spares or special tools.

- Supervision for Installation and Commissioning

The ‘plug and play’ design means there is no requirement for supervision for installation or commissioning. The extremely simple installation is covered entirely by the Installation, Operation & Maintenance manual supplied with each order.

If you would feel more comfortable having guidance on-site, Statiflo can send one of our highly qualified engineers to guide and supervise the installation to give you the confidence that everything is done correctly.

Downloads

Mixer Sizing Questionnaires

Product Brochures

Application Notes

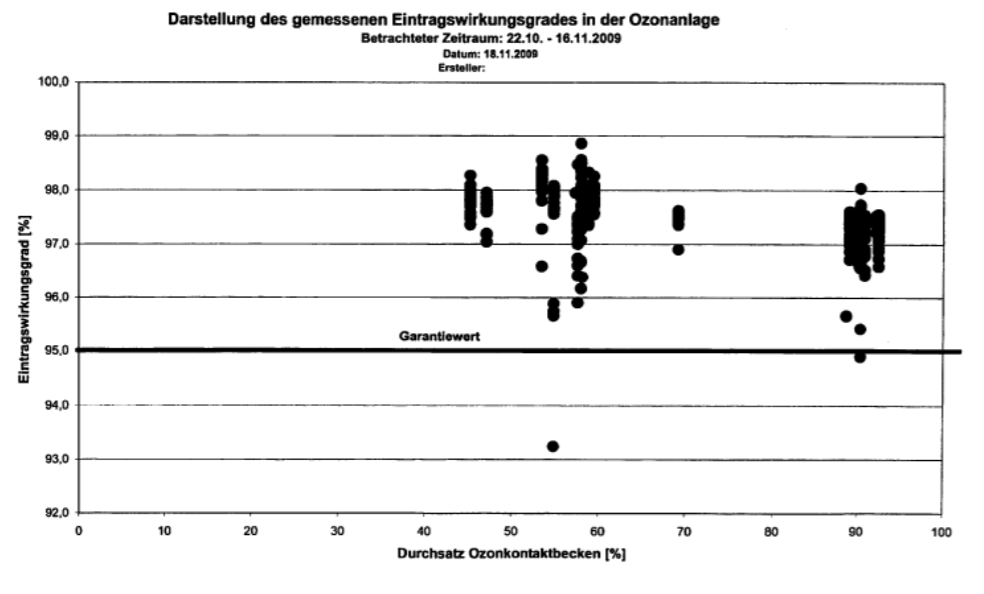

Gas dispersion system for the ozonation of drinking water

Gas Dispersion System: The inline dispersion of a gas in a large volume of liquid…

Case Study

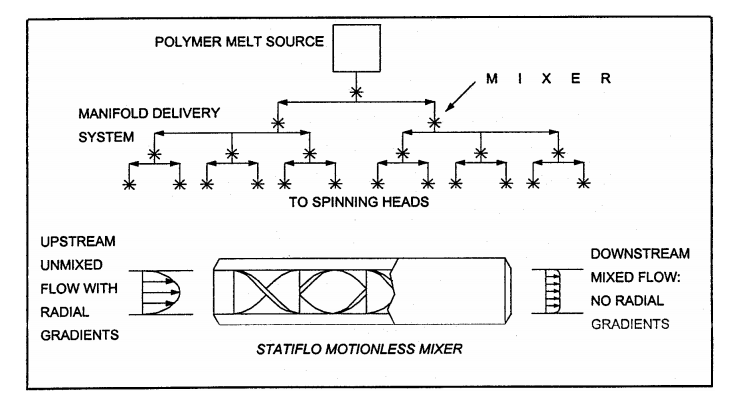

Process with highly viscous polymer melts

Problem A “man-made” fiber spinning plant produces thousands of individual threads simultaneously. All threads come…