Static Mixers For Water Treatment

Table Of Contents

A Comprehensive Guide To Static Mixers For Water Treatment

What Are The Different Types Of Static Mixers?

How Are Static Mixers Used In Water Treatment?

What To Consider When Selecting Static Mixers

What Are The Key Principles In Static Mixer Installation And Maintenance?

What Regulations And Standards Govern Static Mixers?

What Are The Future Trends And Developments In Static Mixer Technology?

A Comprehensive Guide To Static Mixers For Water Treatment

Although three-quarters of the Earth’s surface is covered by water, only a tiny amount – 0.3 per cent in fact – can be used for human consumption, and it is the scarcity of the planet’s most important resource that means effective water treatment is more important than ever.

Water treatment is critical to eliminate impurities and pollutants, thereby ensuring water is clean and safe for human use. Whether it is intended for drinking, in manufacturing processes, or for recreational activities such as swimming, water must achieve exacting standards to prevent potentially serious consequences, including waterborne diseases, gastrointestinal infections, and chemical poisoning. Water treatment is also crucial in manufacturing to prevent impurities affecting quality standards, while it plays an important role in sustainability at a time of increasing demand for finite resources.

In an increasingly cost-conscious world, we are all striving to improve our effectiveness. Process equipment which has no moving parts, which is maintenance-free, very energy efficient and which can improve plant performance, must significantly contribute towards lower operating costs.

Several years ago, the American Institute of Chemical Engineers estimated that inadequate fluid mixing cost the industry 10 billion US dollars per year. We believe that mixing has an even more significant role in the Water Treatment Industry.

In this guide, we’ll explore the role that static mixers play in water treatment, the different types available, and key considerations when choosing static mixers.

What Are Static Mixers?

Static mixers are devices which efficiently mix fluids without the need for moving parts. Consisting of a series of stationary elements placed inside a pipe, tube or channel, they divide, mix, and recombine fluids as they flow through the pipe or tube, resulting in thorough and efficient blending. Complete and predictable mixing avoids the need to overdose chemicals. Not only are chemical savings possible, but the performance of downstream equipment is optimised.

The Statiflo Motionless Mixer is a vital component of any inline mixing/control system. Even the most sophisticated control systems will not perform completely effectively if the measuring equipment fails to see a representative sample. Process control systems are usually very expensive, and despite the Mixer being only a small fraction of the total cost, its role as an essential component, vital to plant performance, is often overlooked.

Installing a Statiflo Motionless Mixer allows sampling immediately downstream, within very few diameters of the injection point. This allows the system to rapidly adjust to monitored process changes with negligible time lag and minimum use of dosing chemicals.

Static Mixers Are Used In Various Industries, Including:

- Water and wastewater treatment to mix coagulants, flocculants, and other chemicals.

- Chemical processing to mix reactants, blend solutions, and promote mass transfer in reactions.

- Food and beverage manufacturing to mix ingredients, blend flavours, and disperse additives in the production of drinks, sauces, and dressings.

- Pharmaceuticals to mix active ingredients, disperse suspensions, and blend solutions.

- Oil and gas industry production to mix additives, chemicals, and inhibitors with hydrocarbon streams.

- Pulp and paper manufacturing to mix pulp slurries, blend additives, and disperse chemicals.

Since they do not require an external power source, static mixers achieve excellent energy efficiency, while their compact size makes them easy to integrate into existing production or process lines. With no moving parts, they offer consistent reliability and require minimal maintenance, making static mixers a cost-effective solution for businesses in many areas of industry in which clean water is non-negotiable.

What Are The Different Types Of Static Mixers?

In water treatment, static mixers efficiently blend chemical additives and promote the thorough mixing of different streams. Which type of static mixer is best for each application depends on several key factors, such as the specific site conditions, flow rates, viscosities, and specific treatment processes involved.

The Types Of Static Mixers Used In Water Treatment Include:

Helical-Type Mixers

Helical-type static mixers are widely used in water treatment for mixing coagulants, flocculants, and other chemicals with the incoming water stream. The helical elements create a swirling flow pattern which ensures effective radial mixing and flow division/recombination. This type of mixer is often designed to both initiate and complete the mixing task within the length of the static mixer.

Helical-type static mixers are the most common type of static mixer available. Generally speaking, their geometry can be customised to allow for specific length or pressure loss requirements. They are most commonly used for smaller pipe diameters.

The Types Of Static Mixers Used In Water Treatment Include:

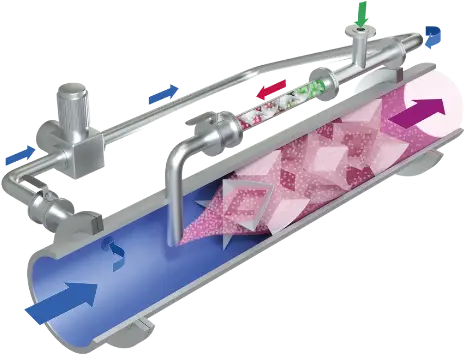

Matrix-Type/Structured Mixers

Matrix- or structured-type mixers can be extremely effective and have various advantages compared to the helical-type design. Due to their more complex geometry, they can achieve a specified mixing objective within a shorter distance than a helical-type mixer. The intersecting elements create intricate flow paths that ensure thorough mixing and the uniform distribution of additives. This type of mixer is often designed to both initiate and complete the mixing task within the length of the static mixer.

They can be used for all kinds of applications within water treatment and are typically more commonly used for larger pipe diameters. The reason for this is that, for a given pipe diameter, a static mixer using matrix-type elements would have a shorter overall length than an equivalent mixer which uses helical-type elements.

Channel Mixers

Channel mixers use mixing elements which are based on the matrix-type design, but have been adapted to be suitable in square or rectangular open channels or closed ducts. Their cellular/modular design allows for adaptation to channels with any aspect ratio – a wide, shallow channel, a narrow, deep channel or anything in between. This unique solution allows for effective chemical dosing in open channels, which has not always been possible.

Compact-Style Mixers

Compact-style static mixers are often preferred in water treatment plants where space is at a premium. Featuring mixing elements that are designed to induce vortices within the fluids, compact mixers provide efficient mixing while minimising the overall footprint. They can be used for various applications, such as chemical dosing, blending of treatment streams, and the rapid mixing of coagulants or flocculants.

In contrast to the other types of mixers mentioned above, compact-style mixers will only initiate the mixing task within the length of the static mixer, and the mixing task is completed downstream of the device.

How Are Static Mixers Used In Water Treatment?

Static mixers are used at different stages of the water treatment process because of their ability to efficiently blend and mix different streams without the need for moving parts.

1) Source Blending

In water treatment plants that receive water from multiple sources, static mixers are used to blend the different incoming water streams to ensure consistent and uniform water quality before proceeding with further treatment processes.

2) Chemical Dosing

Static mixers facilitate the thorough mixing and dispersion of treatment chemicals into the water stream, including coagulants, flocculants, disinfectants, pH adjusters, and other additives that are essential for effective water treatment. Examples include:

3) pH Adjustment

Many water treatment processes, such as coagulation, disinfection, and softening, depend on maintaining an appropriate pH level. Static mixers are used to blend acidic or alkaline solutions with the water stream, thereby facilitating precise pH adjustment and control.

b) Coagulation

Coagulant chemicals play a crucial role in the water treatment process by removing suspended particles, colloidal matter, and other contaminants. During the coagulation process, static mixers are used to rapidly and evenly distribute coagulant chemicals throughout the water. Efficient mixing promotes the destabilisation of colloidal particles and their subsequent removal. This mechanism does not rely on relatively high shear rates, commonly associated with agitators, which would increase the risk of floc degradation.

c) Flocculation

After coagulation, static mixers aid in the flocculation process by gently blending the water stream and encouraging the formation of larger, settleable floc particles that can be easily removed. The gentle mixing action helps to avoid shearing or breaking apart the delicate floc structures which would then be distributed through the water.

d) Disinfection

Static mixers are used to mix and disperse disinfectants, such as chlorine, ozone, or other oxidants, throughout the water stream. Proper mixing ensures effective disinfection and the inactivation of harmful microorganisms that could pose a serious threat to humans if consumed. Statiflo Motionless Mixers can be provided with both injectors and sampling points as integral parts of the equipment, for short time lag and rapid response to system changes.

e) Mixing Of Other Additives

Static mixers are invaluable for mixing various other additives required in water treatment processes, such as fluoride, corrosion inhibitors, scale inhibitors, or any other specialised chemicals necessary for specific treatment objectives.

What To Consider When Selecting Static Mixers

At Statiflo, we have a variety of static mixers that are ideally suited to water treatment processes in different industries. When selecting static mixers for water treatment applications, several factors should be considered:

Flow Rate, Velocity, and Reynolds Number

In water treatment, the flow rates and velocities of the water streams can vary depending on the treatment stage and plant capacity, and play a key role in determining the appropriate static mixer design. The Reynolds number, which represents the ratio of inertial forces to viscous forces, is also an important parameter. Static mixers are designed to operate within specific Reynolds number ranges to achieve optimum mixing. Low Reynolds numbers may require longer mixing lengths or specialised mixer designs to compensate for the laminar flow conditions.

Mixing Objective

Different mixing objectives, such as blending, dispersing, or homogenising, may require different static mixer designs. For liquid-liquid miscible applications, a coefficient of variation (CoV) of 0.05 or less is generally accepted as the industry standard for a good mixture quality.

For other types of mixing tasks (eg. Gas-liquid mixing), other objectives are used as the criteria for determining if the mixing objective has been met, such as bubble size and bubble size distribution. Understanding the specific mixing objective of the application is essential to select the appropriate mixer type and configuration.

Mixing Efficiency

Static mixers are available in various designs and lengths, offering varying levels of mixing efficiency. However, mixer efficiency and mixture quality are often confused, so it is important to understand the difference to ensure that desired performance targets are met. Unlike mixture quality, which defines the mixing objectives, mixer efficiency relates to how the objective will be achieved. An efficient mixer design will have the lowest pressure drop within the shortest mixing length, whereas an inefficient mixer will have a higher pressure drop within a longer mixing length: the outcome, however, will be the same. In independent tests, Statiflo mixers have been proven to have one of the most efficient static mixer designs available on the market, achieving a specified mixture quality within a shorter length and with a lower pressure drop than other devices tested.

Material Compatibility

Static mixers used in water treatment must be compatible with the water quality and chemical additives that are used. Factors such as pH, temperature, and the presence of chlorine or other oxidising agents can impact material choice. Different grades of steel, thermoplastics, and other corrosion-resistant materials are commonly used to ensure long-term durability and prevent fouling or degradation. It may also be the case that in certain territories, relevant water standards may dictate materials which are acceptable for use and allow for product-specific approvals, such as DWI/WRAS in the UK, NSF in the USA or ACS in France.

Installation And Space Constraints

Water treatment plants often have limited space available for the installation of new equipment, but static mixers are often installed in existing pipelines where space constraints may be a limiting factor. Also, the mixer’s installation requirements, such as straight pipe runs before and after the mixer, should be taken into account to ensure proper flow conditions and optimum mixing performance. As all Statiflo mixers are custom-designed for each application and specific site restrictions, our mixers can be installed in the most challenging locations.

Maintenance Requirements

While static mixers are generally low-maintenance devices, some designs may be more prone to fouling or clogging than others, depending on the nature of the fluids being mixed. The ease of disassembly, cleaning, and reassembly should be evaluated, particularly in applications that involve the use of coagulants, flocculants, or other particulate matter. Different static mixing elements are available to handle different types of flow media.

What Are The Key Principles In Static Mixer Installation And Maintenance?

While static mixers offer consistent and reliable performance with little required in the way of maintenance, proper installation is essential, as incorrect fitting will inevitably affect their effectiveness and efficiency. In particular, installers should focus on the following aspects:

✔ Correct Positioning: Static mixers should be installed in locations that maximise mixing efficiency and minimise dead zones or areas of low flow within the pipeline. There should be a sufficient length of straight pipe runs before and after the mixer to ensure proper flow and prevent turbulence or swirling that can disrupt mixing efficiency.

✔ Pipe Alignment: During static mixer installation, the proper alignment of pipes is essential to avoid misalignment, which can lead to uneven flow distribution and reduced mixing performance.

✔ Secure Mounting: Static mixers should be securely mounted and supported to prevent movement or vibration during operation, as this will affect mixing performance and potentially cause mechanical failure.

✔ Gasket Compatibility: The appropriate gasket material should be chosen to ensure compatibility with the fluids that are being mixed and the anticipated operating conditions, as this will help to prevent leaks or premature gasket degradation.

While static mixers have minimal maintenance requirements due to the absence of moving components and can be considered a self-cleaning device due to the fluid’s motion, it is recommended to carry out routine inspections to check for signs of wear, damage, or buildup that may impede mixing efficiency or compromise water quality.

Also, regular cleaning can be carried out to limit potential accumulations of deposits, fouling, or biofilm from static mixer surfaces which can impair performance and cause microbial contamination.

What Regulations And Standards Govern Static Mixers?

Because of the risk to consumers if standards of water treatment are not observed, strict regulations are in place to ensure compliance with health, safety, and environmental requirements.

Regulations and industry standards vary between different jurisdictions, so it is important that static mixers are sourced from a company with extensive experience of supplying equipment across the world, as this will increase the likelihood and ease of compliance. At Statiflo, we have a proven history of distributing static mixers that comply with international safety standards, with many thousands of successful installations throughout the world.

The installation and operation of static mixers is also subject to local health and safety regulations to protect workers from potential harm during the water treatment process. For example, safety standards are established by the Health and Safety Executive (HSE) in the UK and the Occupational Safety and Health Administration (OSHA) in the US whose regulations cover worker safety, fire protection, and the handling of hazardous materials.

What Are The Future Trends And Developments In

Static Mixer Technology?

As in many areas of industry, static mixer technology is continually evolving to deliver even more efficient and cost-effective solutions for businesses who need to achieve exceptional quality standards in water treatment. In the future, it is likely that the following trends and developments will be influential:

Advanced Computational Fluid Dynamics (CFD) Modelling:

Researchers are leveraging advanced CFD simulations to optimise the design of static mixer elements and configurations to predict fluid flow patterns, mixing performance, and pressure drop characteristics with higher accuracy. This will enable the development of more efficient and application-specific static mixer designs.

Additive Manufacturing And 3D Printing:

The adoption of additive manufacturing techniques, such as 3D printing, is expected to revolutionise the production of static mixers. This will facilitate the creation of more complex geometries and intricate mixer element designs that were previously difficult or impossible to manufacture using traditional methods. Also, 3D printing will enable the production of customised static mixers that are tailored to the specific needs of different applications.

Smart Monitoring And Control Systems:

The integration of smart sensors and monitoring systems into static mixer installations will provide real-time data on mixing performance, fouling, and other operational parameters, enabling predictive maintenance and optimised process control. Also, the use of advanced control algorithms and machine learning techniques could enhance the efficiency and reliability of static mixer operations.

Advanced Materials And Coatings:

Researchers are exploring the use of advanced materials, such as high-performance polymers, ceramics, and composites, to address challenges related to extreme operating conditions, aggressive chemical environments, or demanding sanitary requirements.

Modular And Scalable Designs:

Amid soaring demand for greater flexibility, modular and scalable static mixer designs are emerging that can be easily adapted to varying flow rates, mixing requirements, and process capacities. The development of modular mixer elements and configurable systems will allow for seamless scaling and customisation to meet the needs of specific applications.

Find Out More

For more information on our static mixers for water treatment, please call Statiflo today on +44 (0) 1625920270 or send us an enquiry and a member of our team will be pleased to call you back.