In wastewater treatment, the effective introduction of chemicals into the main pipeline stream is crucial…

Statiflo static mixers

A leading producer of bottled mineral water was experiencing problems using a conventional glass bead carbonator for dispersing and dissolving carbon dioxide gas in water. Consistent gas bubble sizes were impossible to achieve without frequent maintenance and lost production.

A further problem with the conventional equipment, which was designed without any particular attention to mixing, was that flavours were periodically accumulating in the carbonator and were then released in slugs resulting in very high flavour concentration in the carbonated water and customer dissatisfaction. Regular cleaning was necessary to minimise this problem.

The company required an answer to both process problems to reduce maintenance and the considerable amount of lost production.

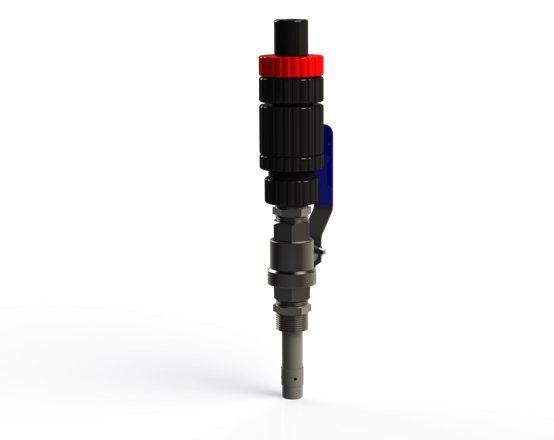

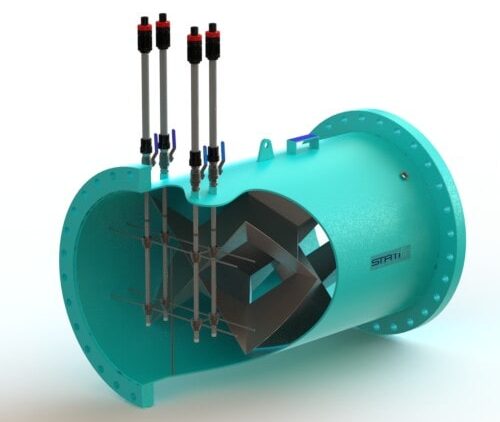

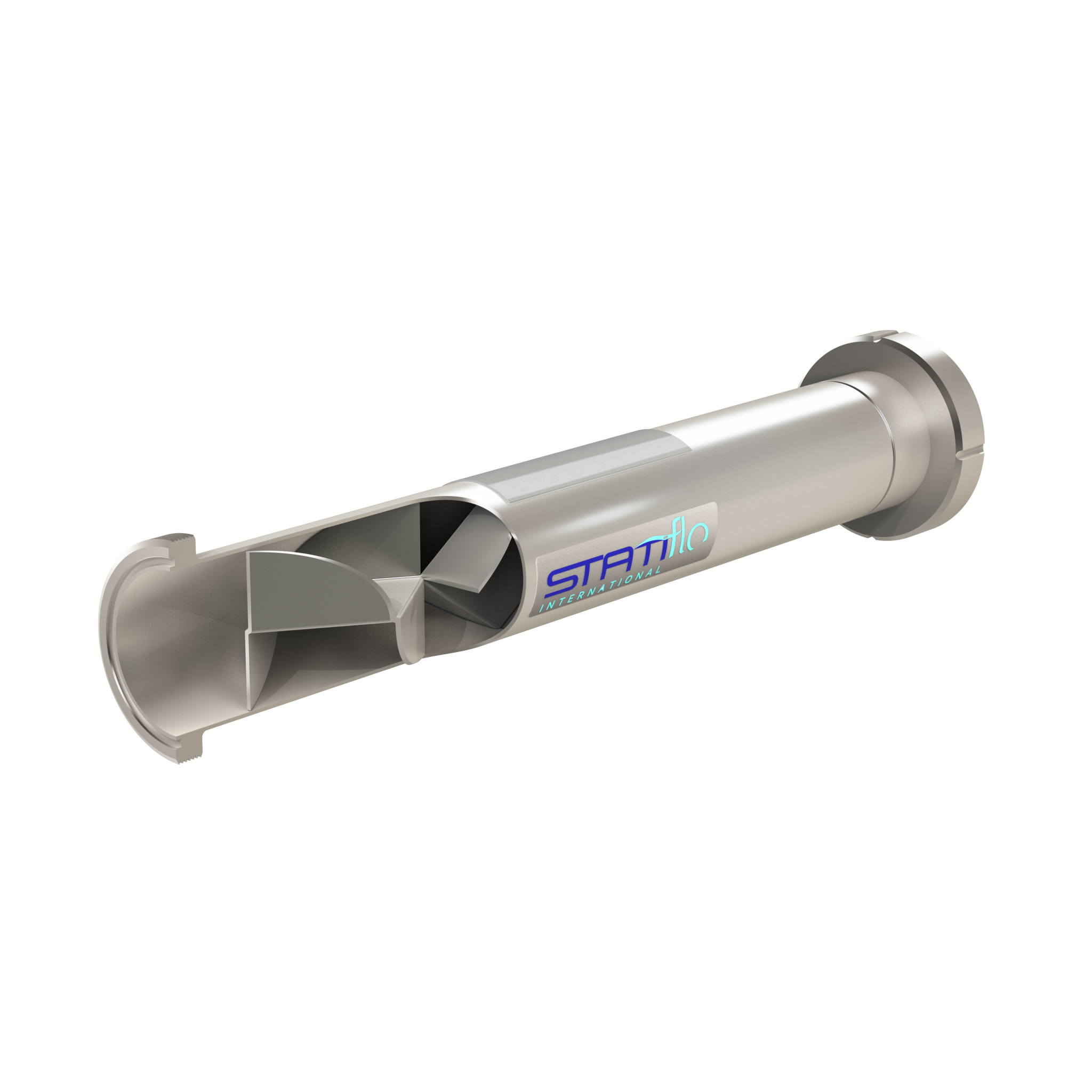

The tank and agitator used for mixing the flavours into water and the glass bead carbonator were both removed and replaced with a Statiflo Series 200 Sanitary Motionless Mixer. This Mixer was fitted with removable elements, RJT couplings and integral injectors for both carbon dioxide gas and flavour.

The Statiflo equipment ensured that total and efficient distribution of flavours and gas was achieved. Gas bubble size and bubble size distribution were predictable due to its almost ideal plug flow characteristic.

The previously complex piping arrangement to the filling machine was greatly simplified as the Statiflo Motionless Mixer is an inline device requiring no direct power supply.

The installation of the Statiflo Motionless Mixer was an instant success. It was soon apparent there was no accumulation of flavour – the Statiflo Mixer is a self cleaning device due to its intense mixing action. Downtime and lost production resulting from the old carbonator was eliminated.

Consistent gas bubble sizes were ensured for efficient mass transfer into solution. Complete and uniform mixing of the flavours was guaranteed. The company had earlier suspected that overdosing was occurring to compensate for lack of mixing. It now had the satisfaction that the efficient operation had eliminated the possibility of wasting flavour.

There were still more benefits – the Statiflo Motionless Mixer operates without moving parts, without spare parts and with virtually no maintenance. The high running costs of the agitator and carbonator were concerns of the past!

The company immediately installed Statiflo Motionless Mixers on all its production lines, after which no more customer complaints were received.

To read the full case study on ‘Carbonating Mineral Water’ please go to the download area of our website.

Inline Static MixerMixing in Wastewater TreatmentPipe MixerStatic Mixer Water TreatmentStatic MixersWaste Water Tank MixersWastewater AgitatorWastewater Treatment MixersWastewater Treatment Plant MixersWater Treatment Mixers