Pipe and Channel Static Mixers used in the Wastewater Treatment and Process

Wastewater Mixing and Treatment: Just like Municipal drinking water treatment, Municipal wastewater and Industrial wastewater treatment and requires chemical dosing for precipitation and flocculation, using organic coagulants or polyelectrolytes.

In the above applications, it is a requirement of the process to mix the chemicals effectively with a large body of water in a very short length of pipe or channel (Wastewater Mixing). This can be difficult as turbulence could be low in some designs of wastewater treatment works. They are designed for settlement and hence the possibility for low turbulence. In these applications the installation of inline or channel mixers is essential for the thorough mixing and process control.

Not only does this require the precise metering of chemicals to meet process demands, stringent consent thresholds or residuals level, but also to perform when operating in a variety of flow conditions. Therefore there is a need to shorten process times and to ensure that any analysers or sampling systems are measuring a representative sample after chemical dosing.

Along with the demands typically present in regular water treatment, wastewater treatment plants feeds will have a certain content of rags, fibrous or stringy materials and generally a high level of solids.

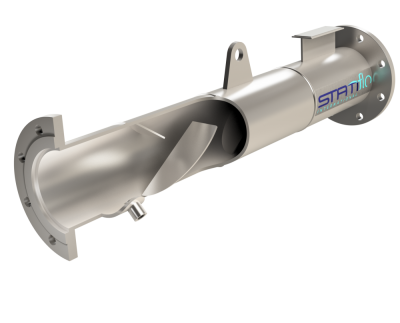

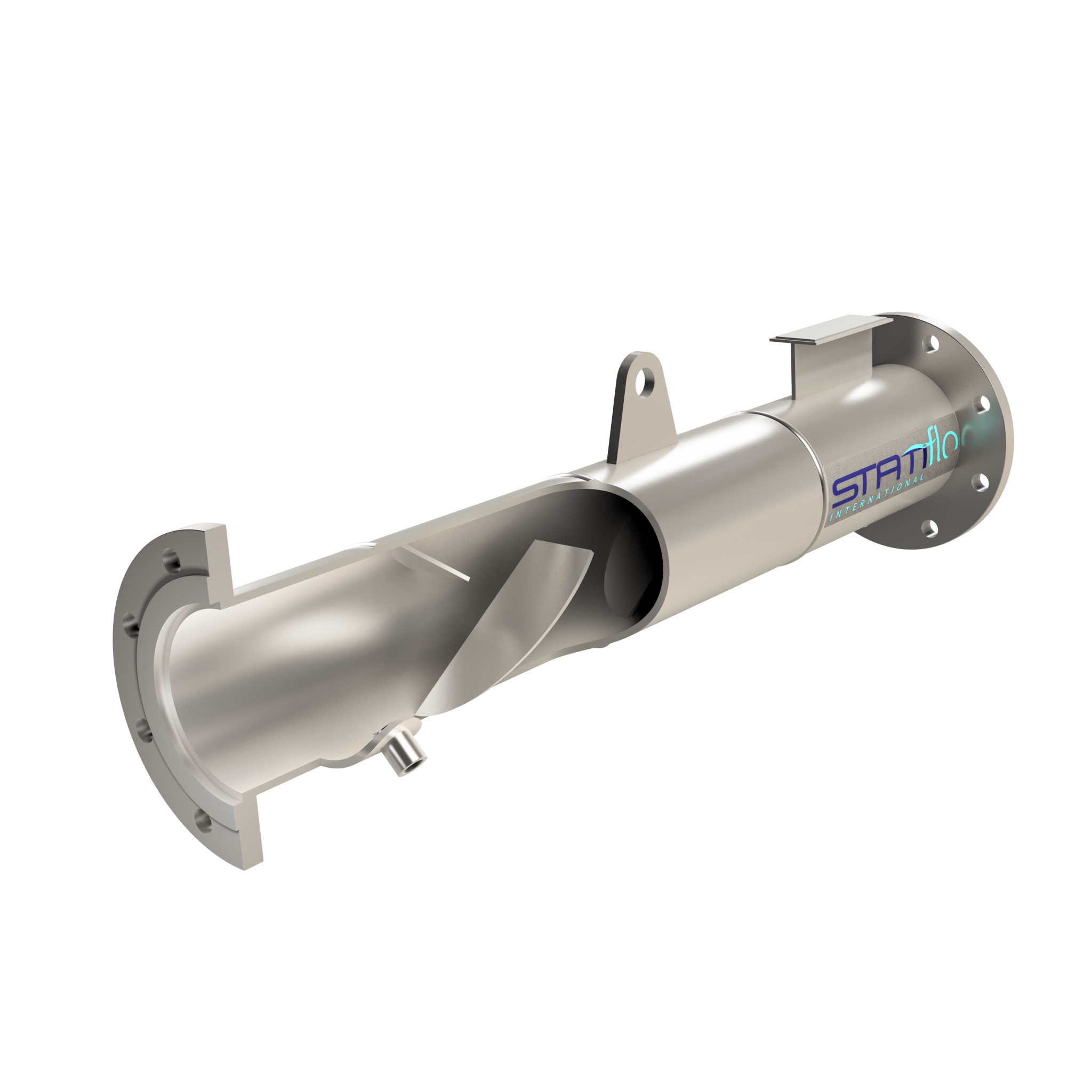

The classic style of static mixer would create issues with such contents and that is why Statiflo has developed the Non-Ragging Static Mixer (also known as the Non-Blocking or Non-Clogging Static Mixer) – a range of Static Mixers designed specifically for the requirements of the wastewater treatment process. The Statiflo Non-Ragging Static Mixer is available in pipe or channel form. We are proud to supply a range of quality wastewater mixing products.

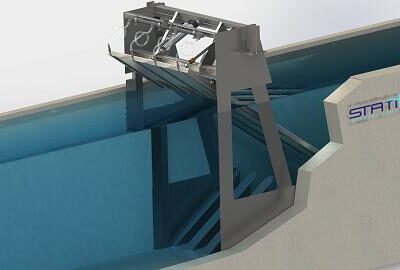

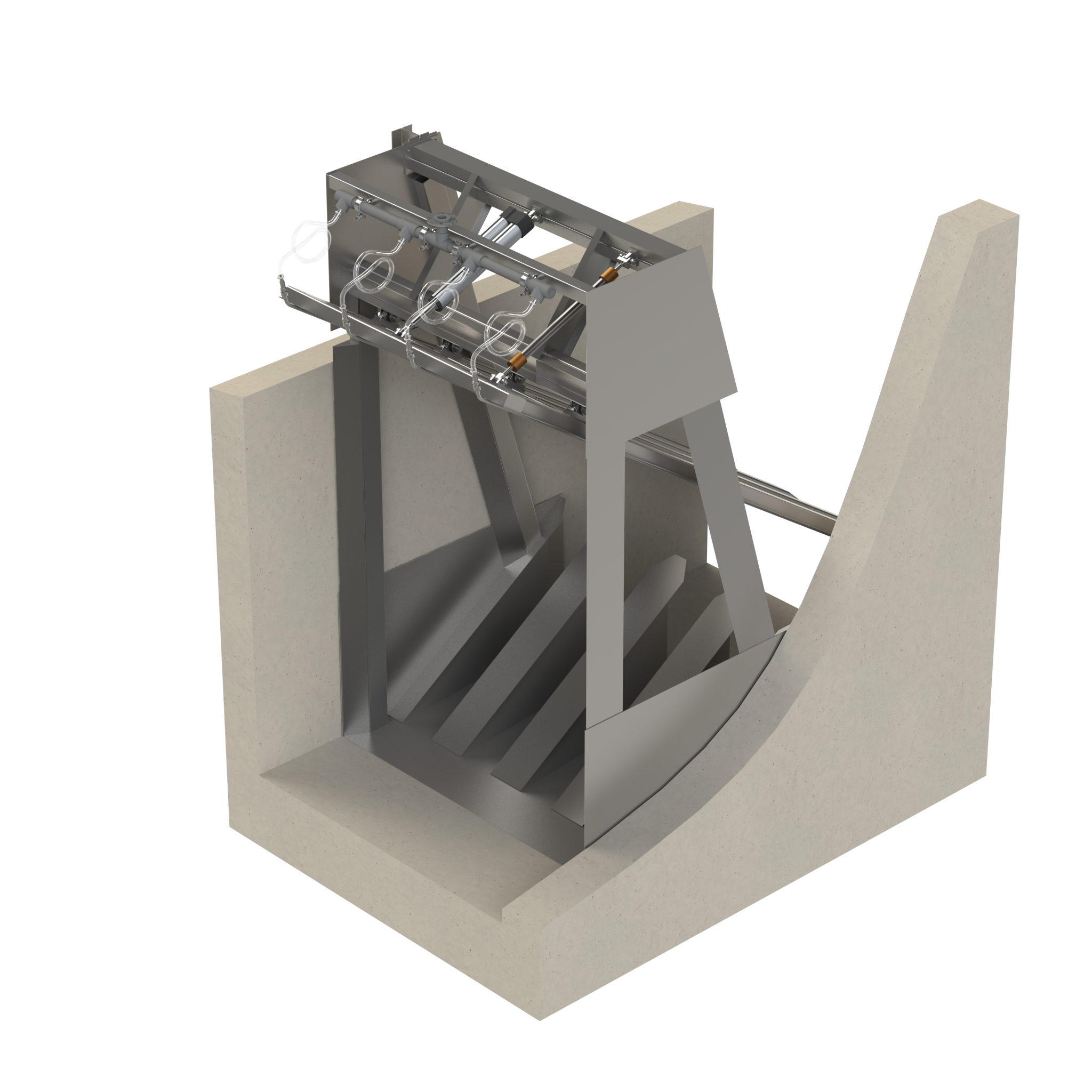

Channel mixing can be challenging, but Statiflo’s unique Non-Ragging Channel (NRC) mixer design makes for a simple installation which can be undertaken in a relatively short period of time and often in live conditions.

With high mixing performance and consistent mixture quality, it is ideal for difficult raw waste water applications where there maybe a high content of rags and/or highly fibrous material.

Applications such as phosphate removal require that chemical dosing is a achieved at strategic points in the process in order to provide efficient treatment to comply with phosphate discharge limits but at the same time avoid overdosing of chemical.

The use of static mixers also provides chemical savings and complements the combined use of biological control.

The above is also applicable for industrial waste water treatment processes.

In assessing the benefits of Statiflo Inline Static Mixers it is important to remember:

- Overall length can be varied to suit space limitations.

- Element geometry can be designed for both high and low head loss systems.

- Large diameter – no theoretical upper limits.

- Elements for rectangular or other unusually shaped ducts and open channels

- Special designs for incorporating in bends, offer space saving and minimal disturbance to piping systems.

- Guaranteed highly efficient mixing.

- No moving parts provide a maintenance free operation.

- Reduction in operational energy costs, as no direct power is required.

- Ease of installation.

- Minimal space requirements with no upstream or downstream pipe lengths required. Providing short control process times in applications where quick process response control is critical.

- Short process chemical dosing control loops provide optimum performance in response to rapidly changing process conditions, as well as reducing chemical costs.

- Available in a wide ranges of sizes and material to suit most applications.

- Each unit is custom designed benefiting from Statiflo’s long term experience in designing and manufacturing static mixers to the highest of standards.

- Total support is provided by highly trained engineers situated in Statiflo regional country offices and a world wide representative network.

Comparing Statiflo’s Non-Ragging Mixer to a Competitor’s Product

- Industrial wastewater treatment with fibres including paperstock

- Sludge blending

- Sludge thickening

- Ferric sulphate and ferric chloride dosing for phosphorous removal

- Coagulant / polymer dosing

- Chemical dosing of sewage

- Industrial wastewater treatment

Case Studies

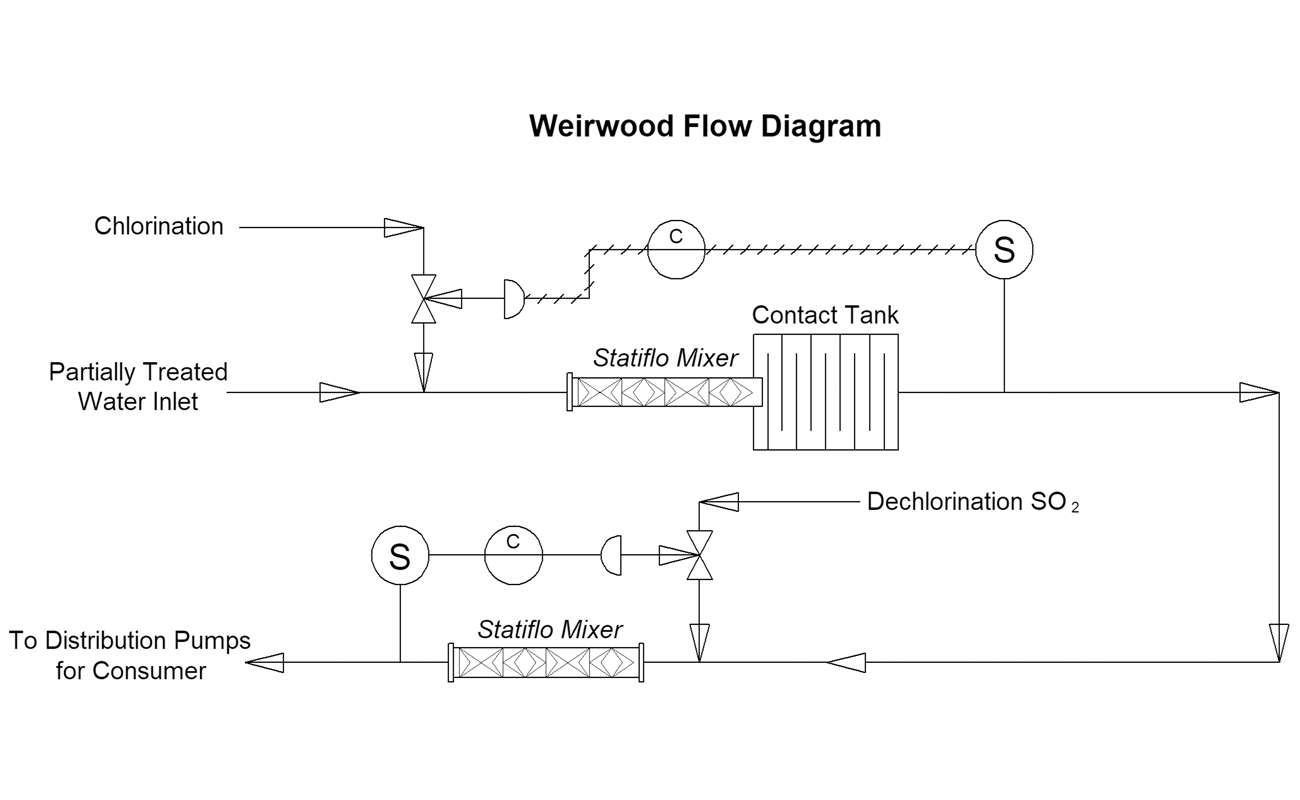

Dechlorination & pH Trim

Problem Dechlorination & pH Trim: Public water treatment plant required highly effective control to dechlorinate and pH trim in difficult access situation. Southern Water’s Weirwood Treatment Works supplies direct to…

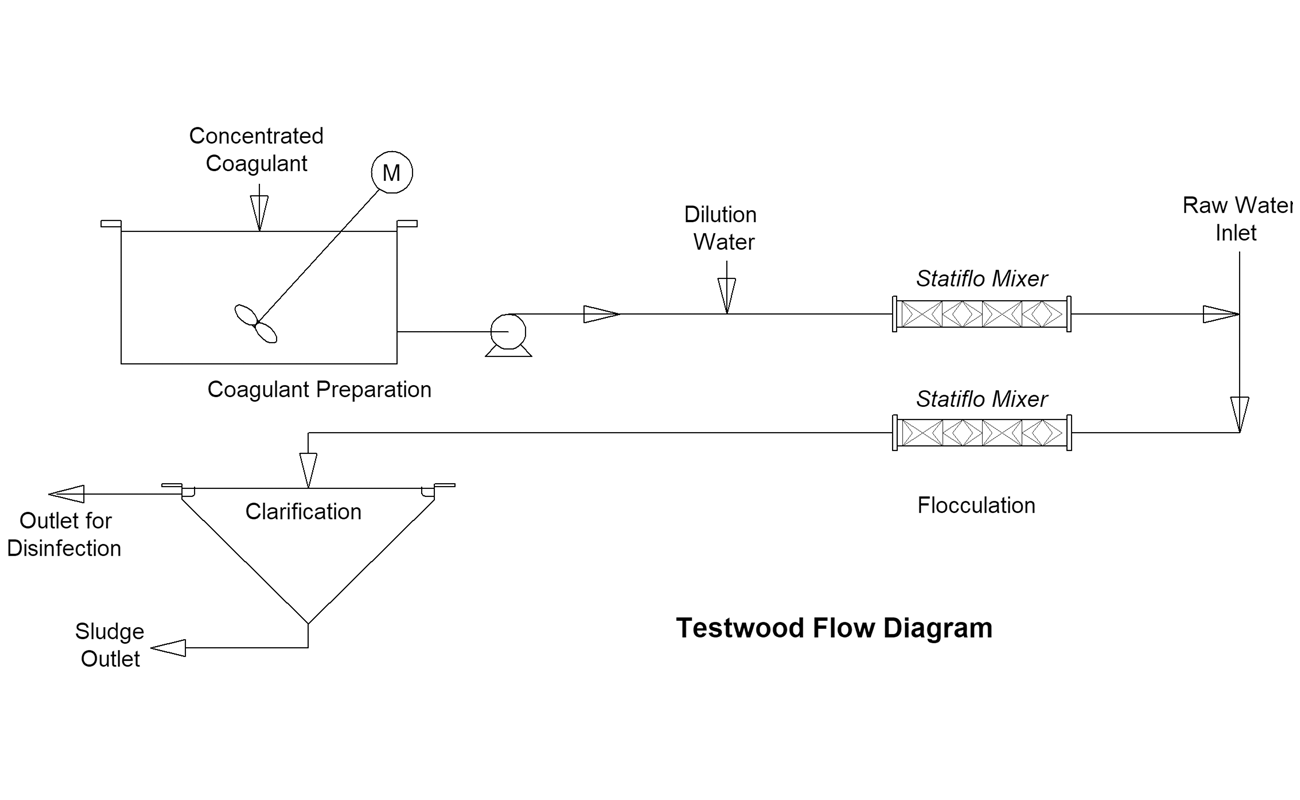

Replacing Inefficient Dynamic Mixer

Problem As part of their policy of constant improvement and updating, Southern Water had identified that an opportunity existed to improve consistency of performance, energy consumption and maintenance costs at…

Related Products

Non-Ragging Channel Mixer

Statiflo Non-Ragging Static Channel Mixer (NRC) A non-ragging static channel mixer for dosing additives into wastewater including raw sewage. …

Non-Ragging Pipe Mixers

Statiflo Non-Ragging Pipe Mixer (NR) The Statiflo NR Pipe Mixer has been specifically designed for sludge mixing or wastewater applications with…

Customers Include