Static Mixers Vs Dynamic Mixers: Which Is Right For Your Process? In many industrial applications,…

Nestle, manufacturers of the world’s number one confectionery assortment ‘Quality Street’, have completed important process enhancements to their production facility after requesting Statiflo’s mixing expertise to improve the appearance and consistency of the caramel content. Statiflo engineers custom designed a jacketed static mixer for mixing two different temperature and viscosity caramel streams. Hot water within the jacket heats the caramel at the pipe wall and this heated caramel is forced by the closely fitted mixing elements to the core, whilst the cooler core product is moved to the heated wall zone achieving a uniform temperature profile immediately at the mixer discharge.

The Statiflo Series 200 sanitary design 2” OD mixer supplied creates a completely homogeneous mixture with a theoretical 4096 layers of caramel each 14µm thick. The pressure drop across the Statiflo static mixer is less than 0.1 bar. The installation of the Statiflo static mixer has made a considerable difference to the finished blended caramel quality, also improving its physical appearance.

On the back of this success Nestle are now looking at other areas within their production which could be improved using Statiflo static mixers.

For further information on this story please contact [email protected]

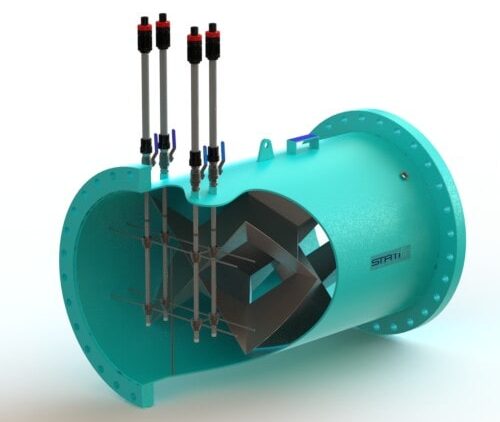

Mixing in Wastewater TreatmentStatic Mixer Water TreatmentStatic MixersWaste Water Tank MixersWastewater AgitatorWastewater Treatment MixersWastewater Treatment Plant MixersWater Treatment Mixers