Problem

The inline dispersion of gases into large volumes of liquids is often performed using complex equipment, usually involving large compressors, pressurised gas containers and fine bubble diffusers.

In many cases in the water treatment industry, this type of approach is a complicated and extremely expensive method of simple gas dispersion – a classic example being the oxidation of soluble iron in water using air or oxygen.

Solution

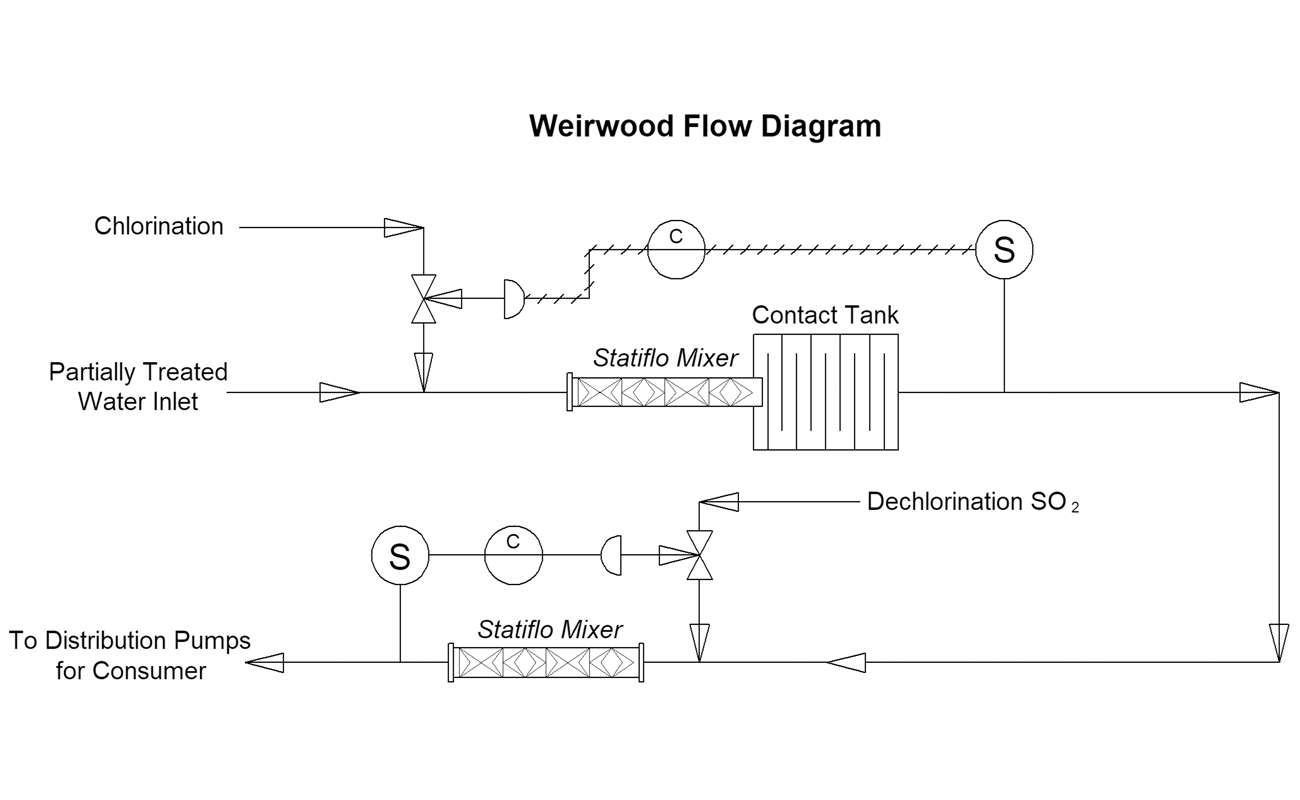

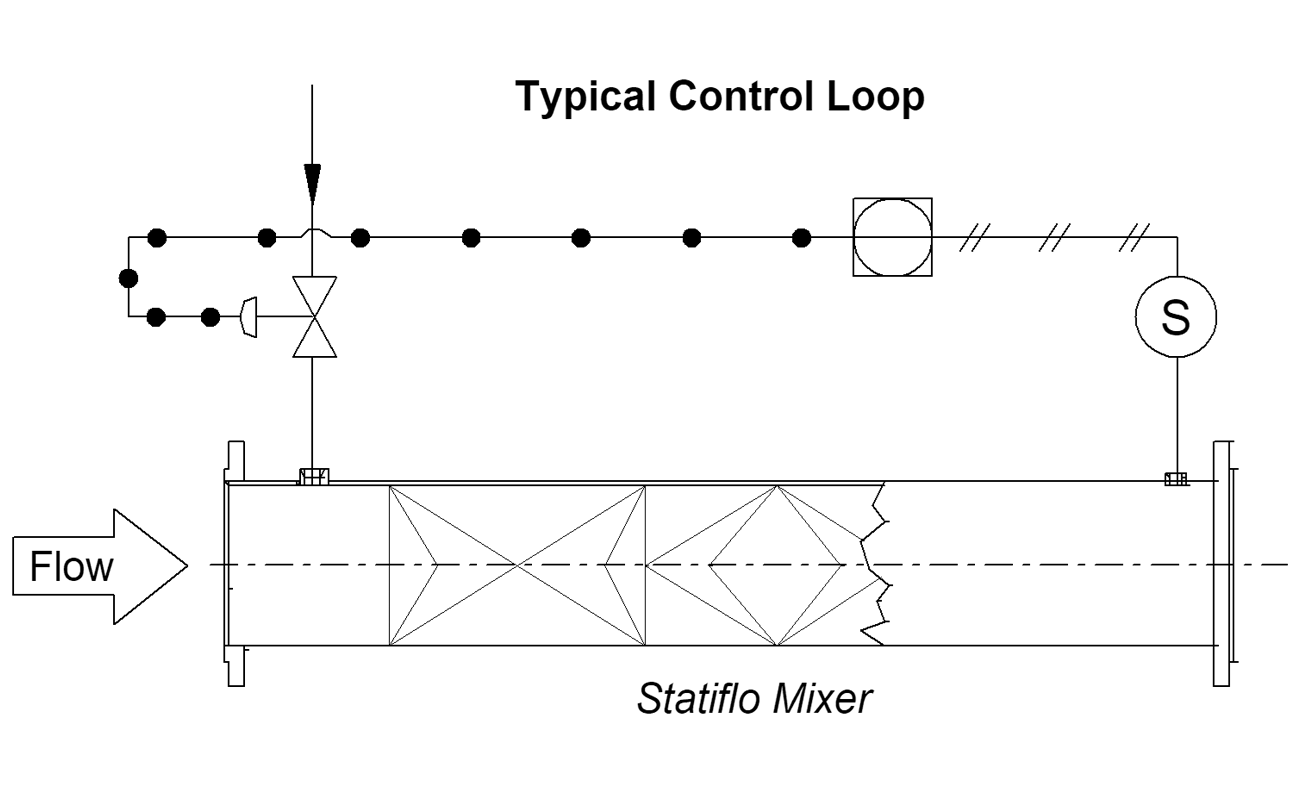

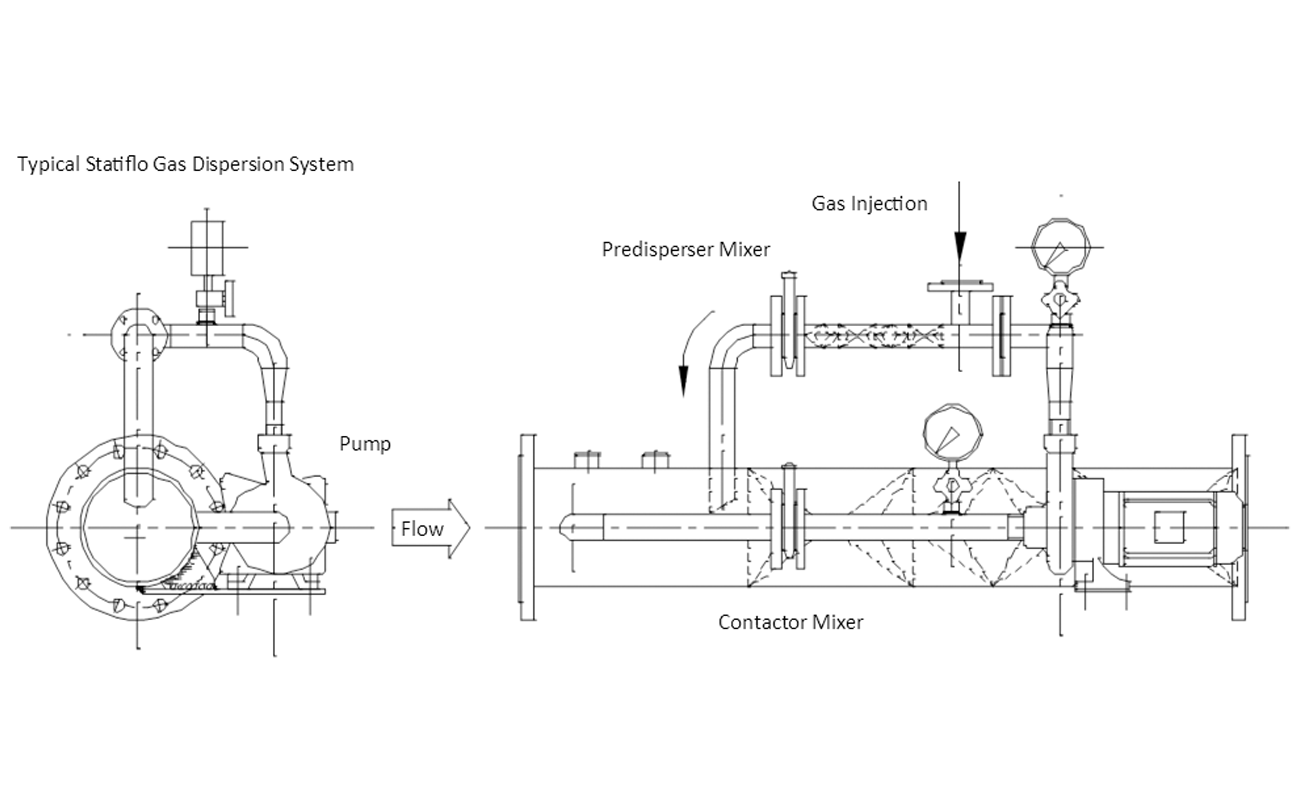

The use of a combination of Statiflo Mixers has resulted in an extremely simple, cost effective and efficient alternative solution. The Statiflo inline gas dispersion system consists of a large diameter gas contacting static mixer, supplied as a flanged pipework component designed to bolt directly into the existing pipework system.

Attached to this, as part of an integral package, Statiflo provide a small motive water pump, a small diameter gas dispersion static mixer, interconnecting pipework, valves and gauges for a self contained system. The motive water pump withdraws a small flow of untreated water from the inlet of the gas contacting static mixer and passes it through the small predispersion static mixer, where gas is injected at ideal dispersion velocities.

This results in an intimate mixture of fine gas bubbles and water which is then injected into the large diameter gas contacting static mixer. The two phase flow is uniformly dispersed into the main water stream, ensuring optimum gas/liquid contact and highly efficient mass transfer.

Result

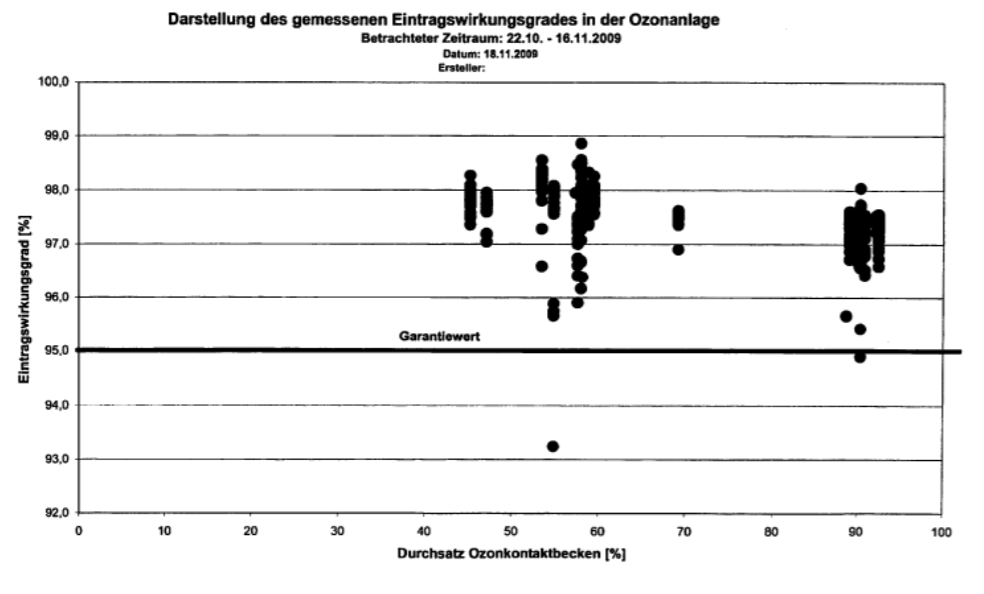

Efficient continuous mass transfer is achieved with low installed and operating costs and with minimal maintenance.

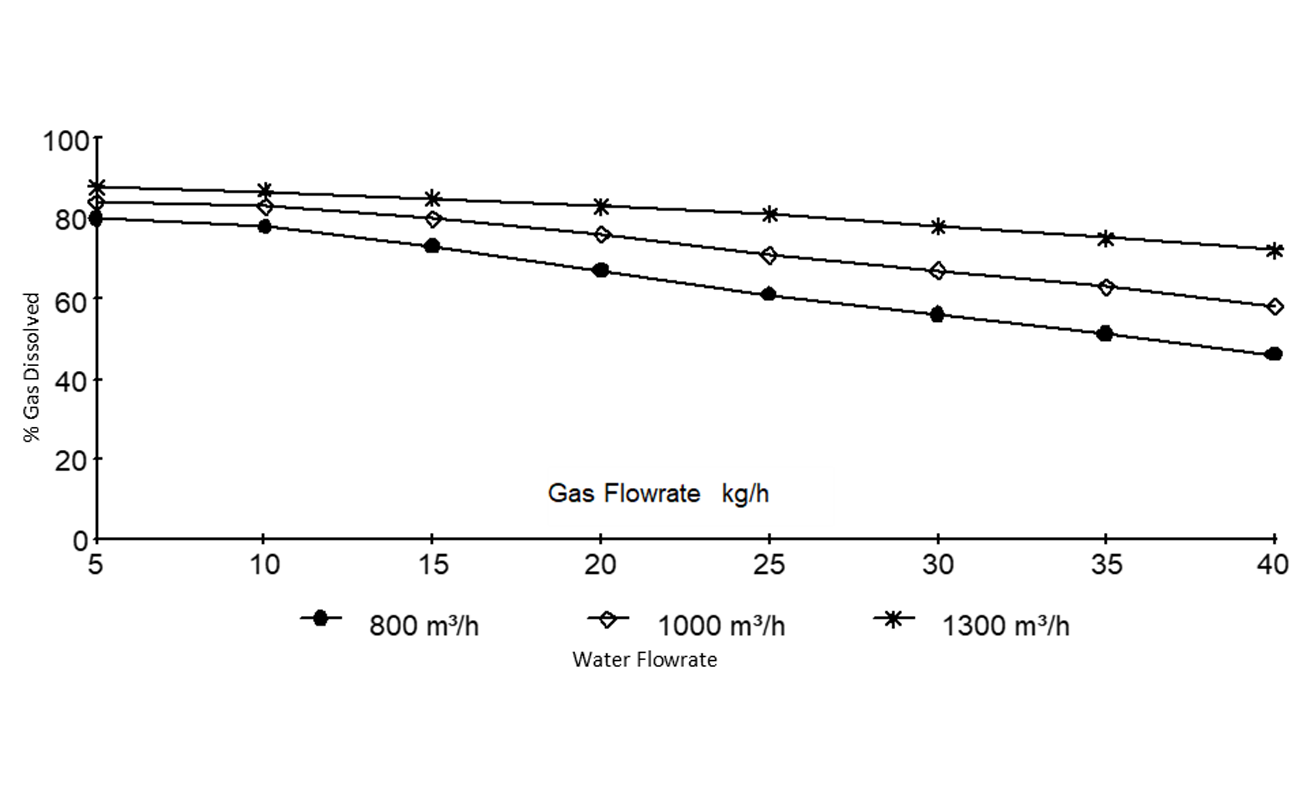

As the gas bubble size is a function of the predispersion mixer flowrate and not the mainstream water flowrate, the systems maintains high efficiency at low flowrate conditions.

Whether the application is oxidation of soluble iron with air, the aeration of potable water with oxygen or ozone treatment, the Statiflo gas dispersion system provides the ideal combination of cost and efficiency.

- Competitive price compared with traditional methods of gas dispersion and mass transfer

- Extremely simple installation procedure

- Economic operating costs

- Consistent and predictable performance

- Minimal space requirement

- Completely sealed system

- Self cleaning

- Available in all sizes

- Available in any material

- Custom designed

- Meets all QA/QC levels

- Available worldwide