Statiflo Awards We were thrilled to honor four of our outstanding US business partners at…

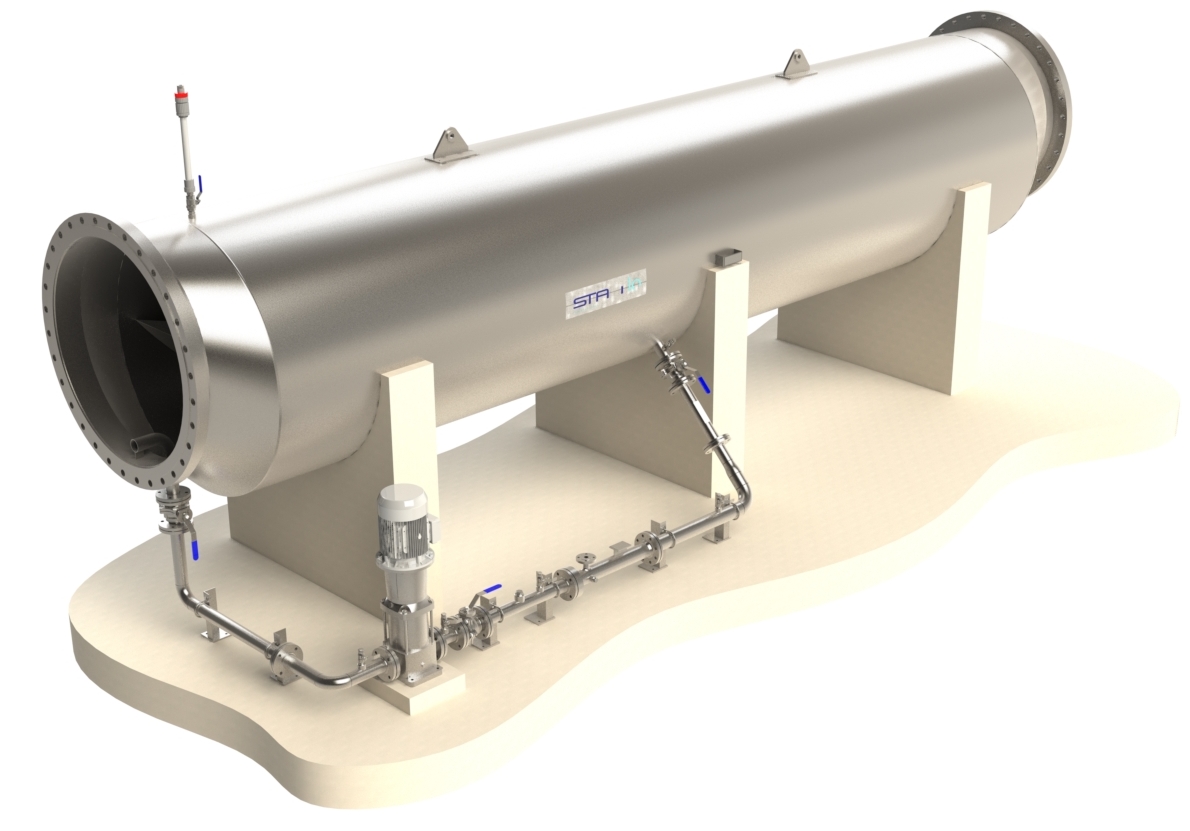

In wastewater treatment, the effective introduction of chemicals into the main pipeline stream is crucial to achieve optimum treatment results. Chemical injection lances play a vital role in this process as a means of precisely introducing chemical agents into the wastewater flow. As well as using pipe static mixers in your wastewater treatment, selecting the right injection lance can also significantly impact the efficiency and safety of the industrial process.

Choosing The Right Chemical Injection Lance For Your System

Injection lances are designed to work in tandem with dosing systems, allowing for precise chemical injection into the main pipeline at a specific location. They should be used in conjunction with inline static mixers, injection lances ensure that injected chemicals are fed to the static mixer at a precise location relative to the mixing elements to enhance the overall effectiveness and efficiency of the treatment process. A common misconception is that injection lances can be used in place of static mixers, but it has been independently proven that the use of a chemical injection lance, where no mixing device is installed, can result in a distance of up to 200 pipe diameters being required to achieve a suitable mixture quality.

So, what are the main factors you should consider when choosing a chemical injection lance?

In industrial processing, cost-saving measures that maintain quality and performance are invaluable for businesses, enabling them to slash their overheads while improving their profits. Inline static mixers offer many benefits, and in this article, we’ll look at how an industrial static mixer can save your business money.

1. What Is The Pressure Of Our Dosing Lines?

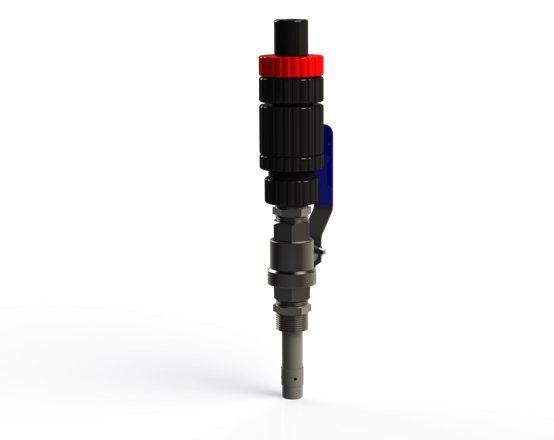

When choosing a chemical injection lance for your industrial wastewater treatment processes, a key factor to consider is the operating pressure of the system. Certain designs, such as the XHP (Extra High Pressure) dosing lance, are engineered to withstand higher pressures than standard lances, a feature that not only expands the range of applications for which it can be used but also ensures that stringent health and safety requirements are met.

2. Is A Threaded Wind-Out Design Mandated?

The XHP dosing lance incorporates a threaded wind-out design, a feature that is mandatory on some sites due to enhanced safety regulations. All Statiflo’s lance designs allow the lances to be withdrawn under pressure, eliminating the need to fully depressurise or drain the main line during maintenance operations, thereby reducing downtime.

3. How Will Environmental Conditions Affect The Material Of The Lance?

Material selection is another critical aspect when choosing a chemical injection lance. Depending on the nature of the chemicals being introduced to the wastewater stream, injection lances can be manufactured from various materials, including uPVC, stainless steel, or Hastelloy. Selecting the most appropriate materials will ensure compatibility with a range of corrosive chemicals, preventing premature degradation and prolonging the service life of the equipment.

Contact The Specialists At Statiflo Today.

To find out more about how we can help to improve your industrial processes, or for professional advice to choose the best chemical injection lance for your wastewater treatment system, please contact Statiflo today to chat with our experts.